#statusMessage#

Do you want to start the comparison now?

#statusMessage#

Do you want to start the comparison now?

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Disturbances in the power grid often go unnoticed until systems shut down or equipment fails. Regular power quality asse...

In this practical checklist you will learn how to calibrate your measuring and test instruments effectively – simply, ef...

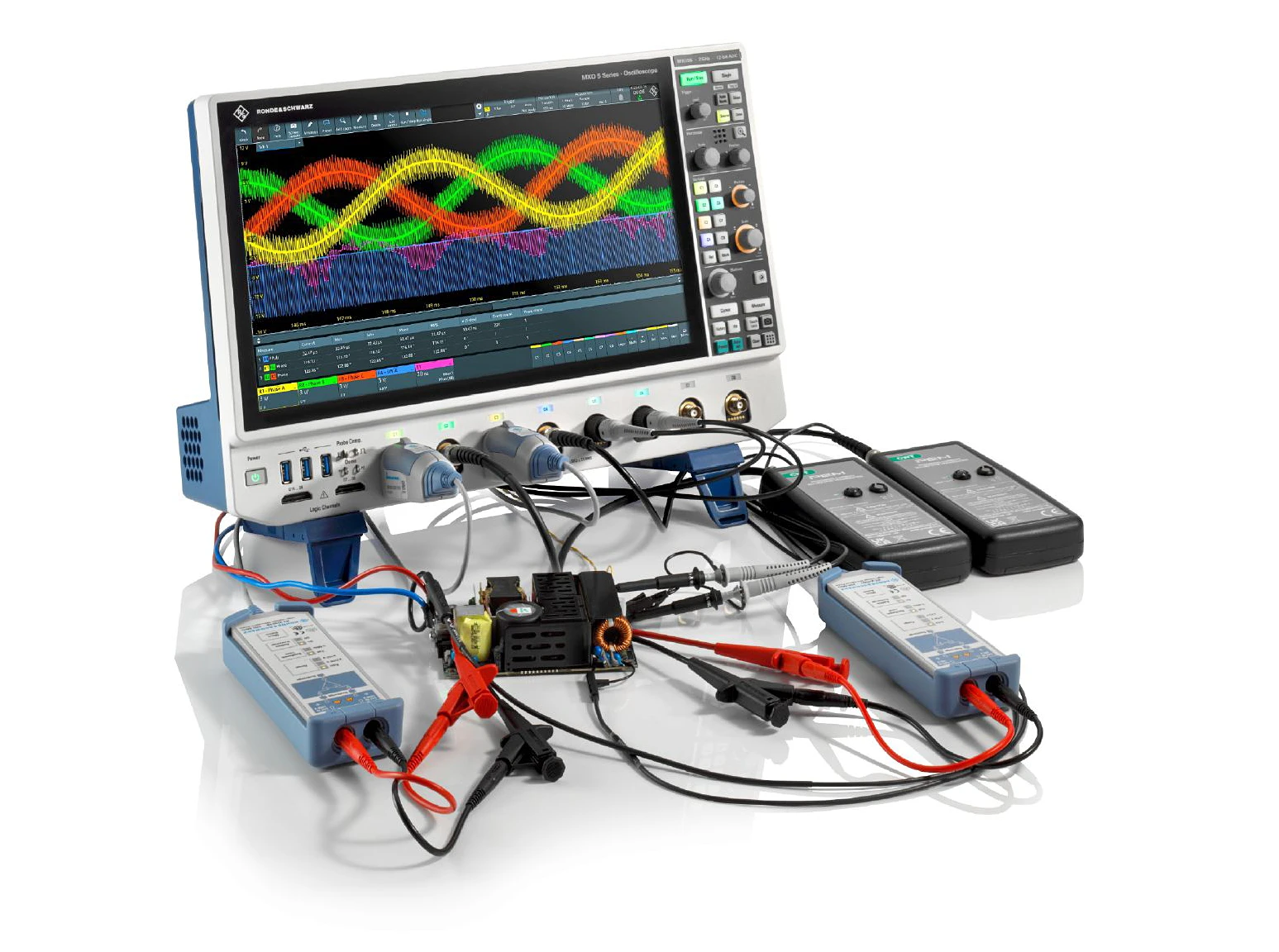

Modern oscilloscopes of the MXO Series from Rohde & Schwarz enable precise analysis and optimization of electric drivetr...

Manufacturer number: 825040201

| Article number: | 825040201 |

|---|---|

| Dimensions (L x W x H) (mm): | 164.3 x 201.3 x 84.1 |

| Focus: | manual, autofocus (contrast/laser) |

| Frame rate (Hz): | 30 |

| Image enhancement technology: | MSX, UltraMax |

| Image memory: | SD card |

| Interchangeable lenses: | Yes |

| Interfaces: | USB |

| Max. field of view (FOV): | 14° x 10° |

| Model: | T840 14°+24° |

| Resolution in pixels: | 464 x 348 |

| Smallest resolution IFOV (mrad): | 0.52 |

| Temperature measuring points: | 161,472 |

| Temperature measuring range: | -20°C to +1500°C |

| Thermal sensitivity (mK): | 40 |

| Weight (kg): | 1.4 |

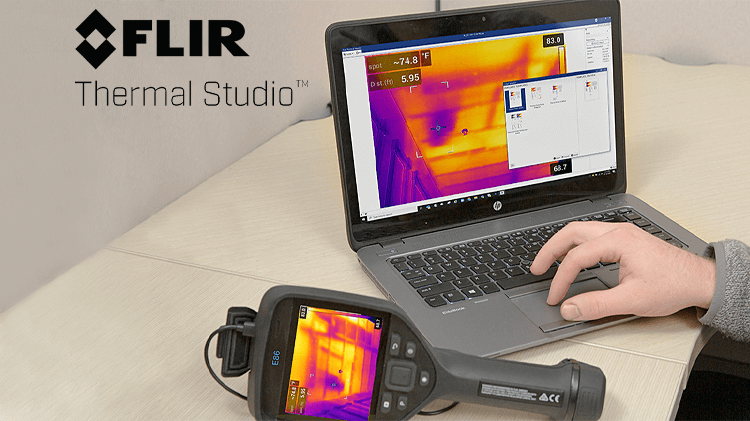

The Flir T840 noticeably simplifies and accelerates the internal and external monitoring of electrical systems, the identification of defective components and many other thermal tests. Carry out tests, inspections and maintenance quickly, easily, flexibly and without excessive physical strain. The bright, 4-inch color LCD display, including built-in viewfinder, enables you to carry out inspections even in the most difficult lighting conditions. Thanks to the high resolution of 464 x 348 pixels, you can carry out inspections from a safe distance. Of course, the Flir T840 is equipped with FLIR Vision Processing ™, MSX® and UltraMax® and thus provides you with an optimized resolution with up to 645,888 pixels.

The Flir T 840 has a particularly ergonomic design and an optical unit that can be swiveled through 180 °. This enables you to identify thermal irregularities, even in places that are particularly difficult to access, without dislocations, almost instantly.

A 6 ° telescope is optionally available, which enables you to take precise measurements even over long distances.

Wireless WiFi streaming to the FLIR Tools app enables simple real-time checking of problem areas. In addition, the GPS sensor integrated in the camera automatically provides the image files with the associated geolocation data in order to simplify their identification and precise documentation.

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Discover our selection of intrinsically safe multimeters, pressure calibrators, milliohmmeters, thermal imaging cameras ...

In order for the inspection of buildings and systems to lead to decision-relevant information, the precise evaluation of...

In the second episode of dataTec unboxed, we present the Ex Pro thermal imaging camera series from FLIR. Discover suit...

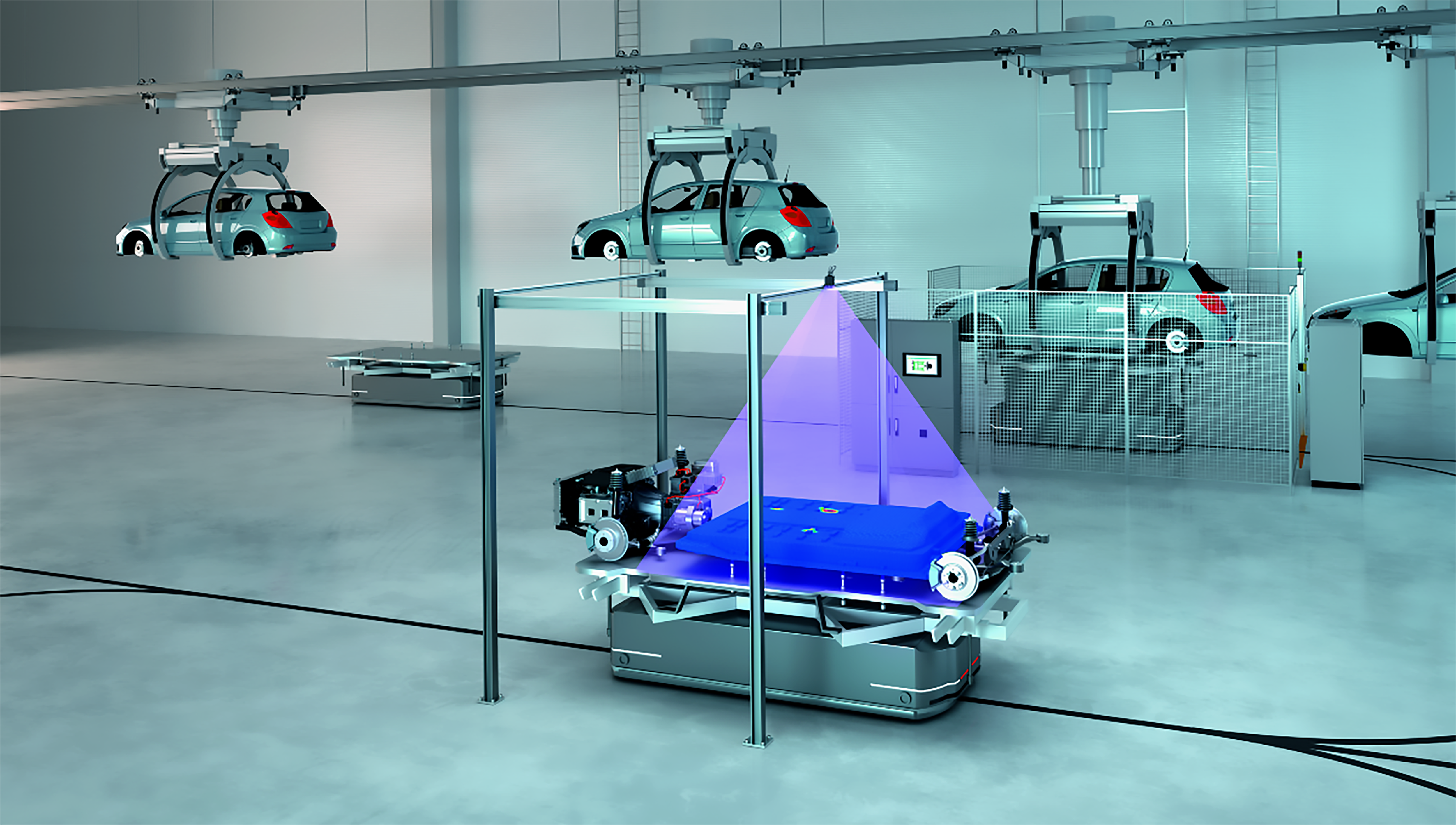

Automation with thermal imaging technology has proven to be a reliable solution for quality control in various industrie...

Thermal imaging cameras are quickly ready for use and easy to operate – directly on site: for example in buildings or pr...