#statusMessage#

Do you want to start the comparison now?

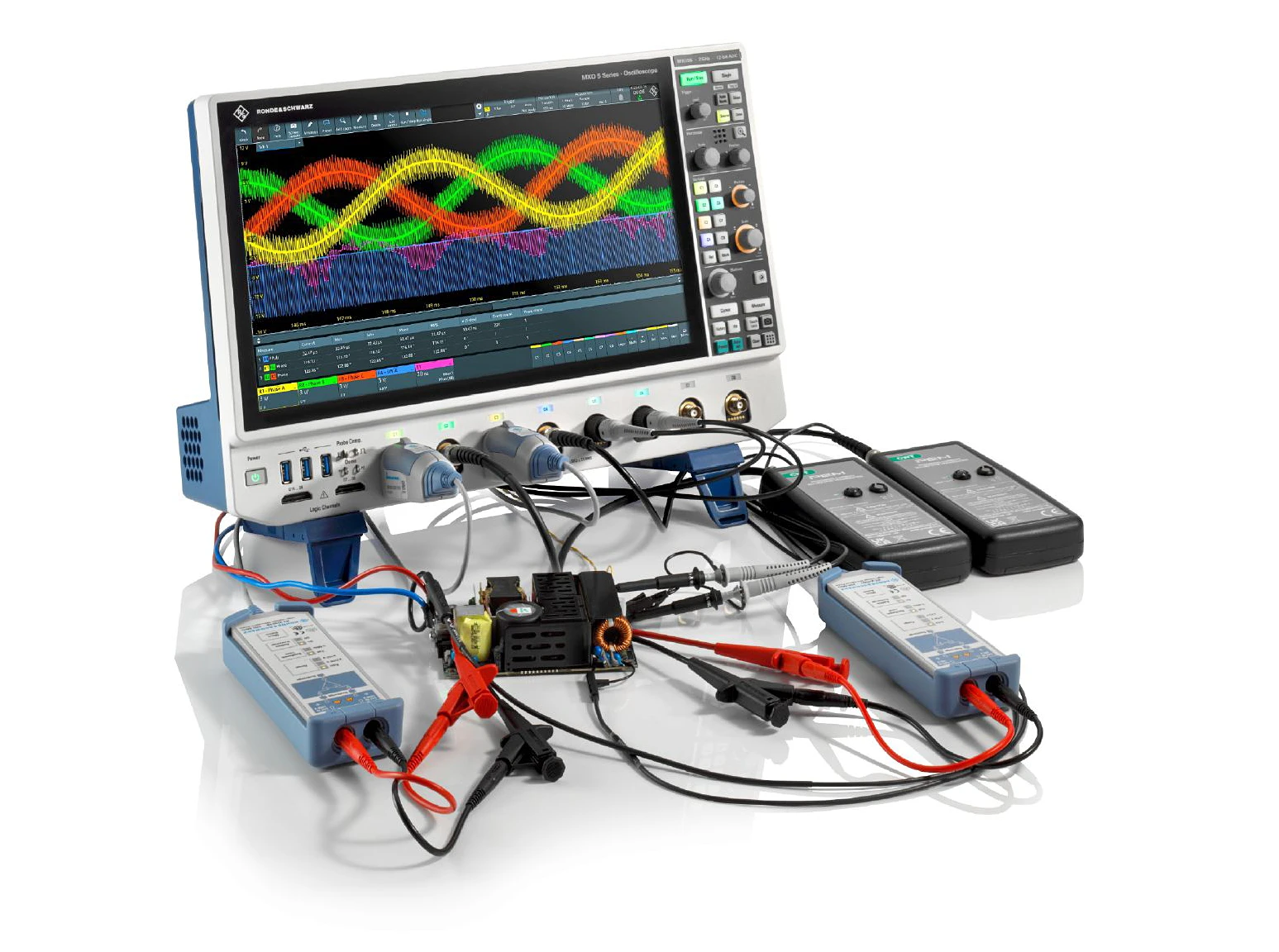

Modern oscilloscopes of the MXO Series from Rohde & Schwarz enable precise analysis and optimization of electric drivetrains. Discover how complex measurement tasks along the energy flow can be efficiently managed and what advanced capabilities the new MXO3 offers for future measurement and testing requirements.

Discover products nowThe electrification of the drivetrain poses new challenges for engineers:

From energy conversion in the inverter to motor control, voltages, currents, and switching events must be thoroughly understood in order to optimize efficiency, dynamics, and reliability.

Modern oscilloscopes play a key role in this process.

They enable precise time- and amplitude-based analysis of electrical and mechanical phenomena, providing deep insights into system behavior – in real time.

With the new MXO Series from Rohde & Schwarz, a new generation of oscilloscopes is available that masters these tasks with previously unmatched precision and speed

Its latest model, the MXO3, sets new benchmarks in user convenience, resolution, and signal acquisition.

Performance characterization of an electric drivetrain involves numerous measurement points:

From the DC battery input through the DC link to the three-phase AC outputs of the inverter, voltages, currents, and switching times must be captured precisely.

The goal is to understand the complete energy flow:

Equally important is the validation of motor control. Control algorithms must be tuned so that torque and speed accurately follow their setpoints. With its high sampling rate and multiple acquisition channels, the MXO Series provides a comprehensive overview of all relevant measurement points – simultaneously and synchronously.

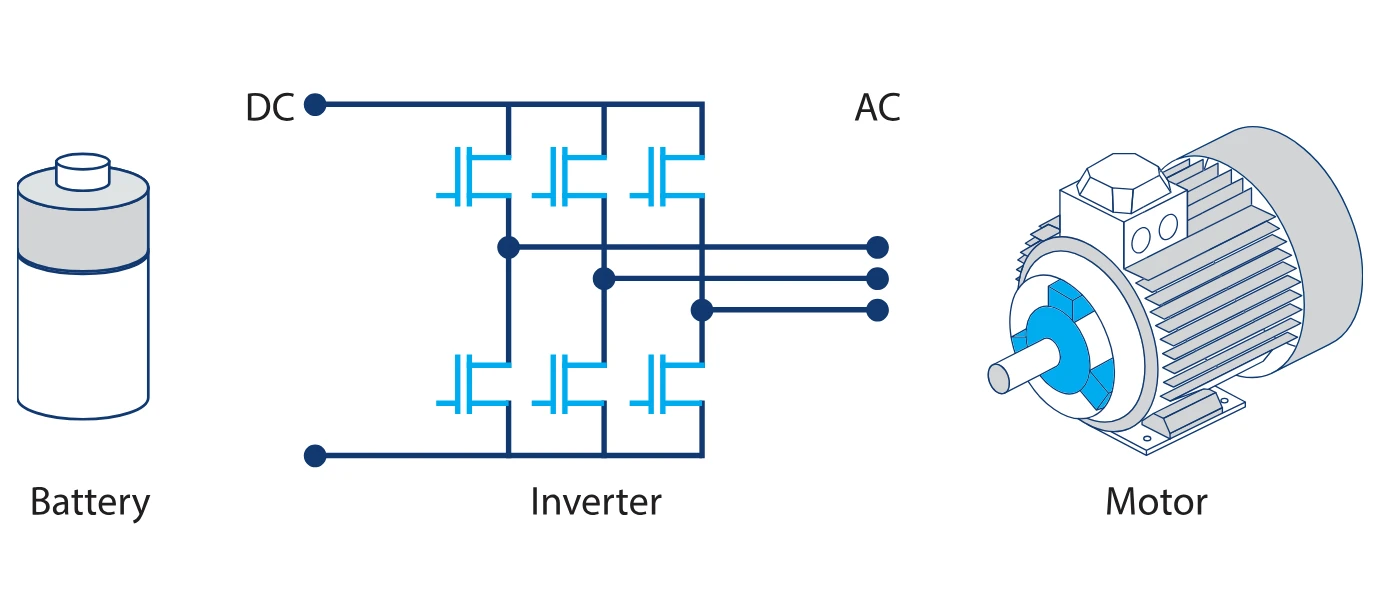

The inverter is the heart of the electric drivetrain. It converts the battery’s DC voltage into a torque-controlled AC voltage. Transistor control is achieved via Pulse Width Modulation (PWM). These fast switching processes create complex signal shapes that can only be accurately captured with high-resolution measurement systems.

For a complete analysis, all three phases must be observed simultaneously – including the control signals of the IGBTs or SiC MOSFETs. Even minimal timing deviations between high- and low-side gates can lead to so-called shoot-through events that thermally overload components.

The digital trigger architecture dof the MXO Series enables precise detection of such events. Even the smallest glitches or unintended overlaps between gate signals are reliably captured.

Fig. 1: Three-phase inverter – basic structure and measurement points (U, V, W).

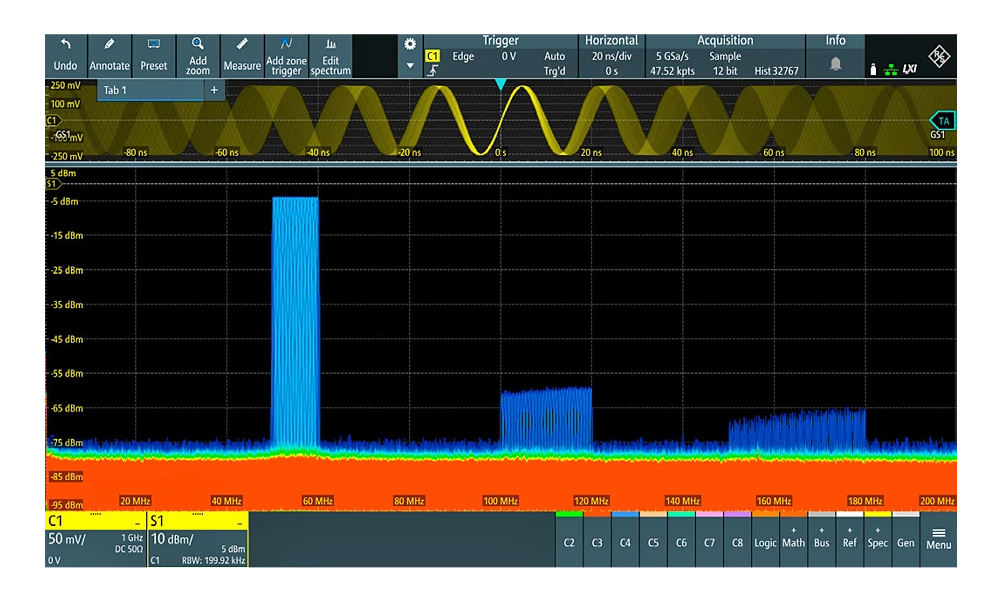

MXO oscilloscopes combine high-speed time-domain analysis with powerful frequency-domain tools:

This allows voltage and current waveforms to be visualized not only in the time domain but also analyzed spectrally.

Harmonics, distortions, and EMC disturbances become visible in real time – a decisive advantage when optimizing filters and control logic.

Fig. 2: FFT analysis of a PWM signal chain for evaluating EMC behavior.

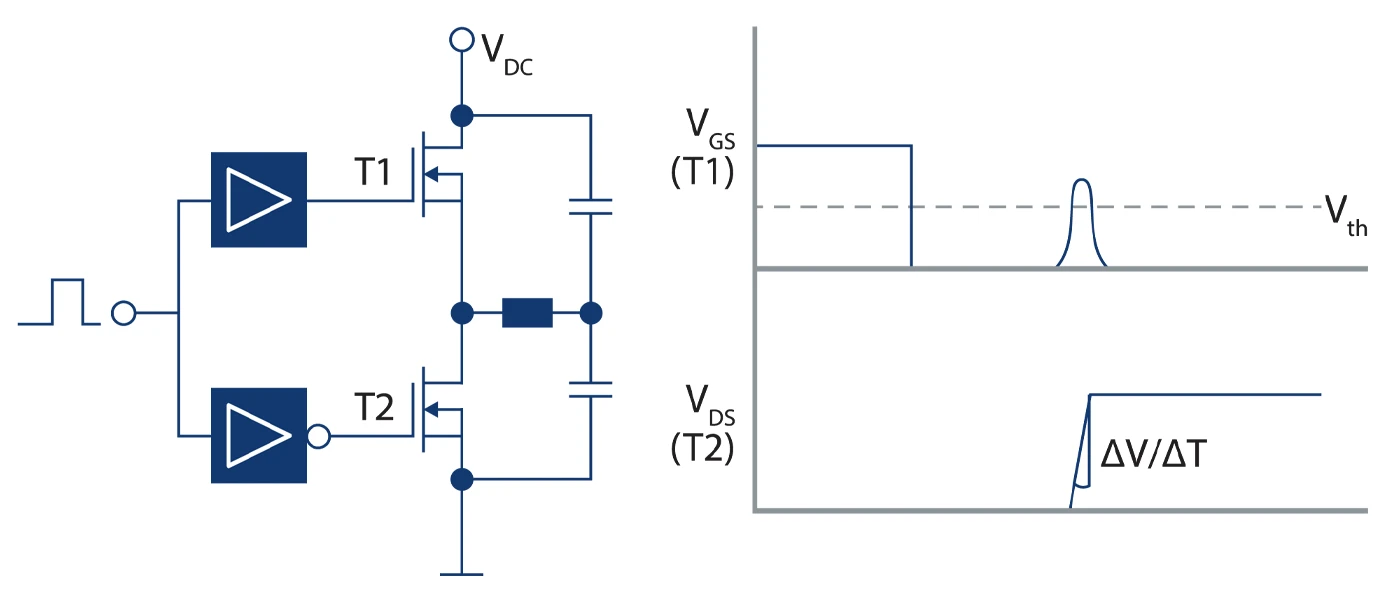

Fast switching events in modern SiC transistors require precise timing analysis.

The MXO simultaneously captures gate voltages and drain-source waveforms, allowing evaluation of the dead-time between high- and low-side switches.

Fig. 3: Analysis of a SiC gate signal with digital trigger for shoot-through detection.

Using the integrated track function, variations in pulse width or switching frequency can be monitored over extended periods.

This enables developers to understand how load changes or temperature influence switching characteristics.

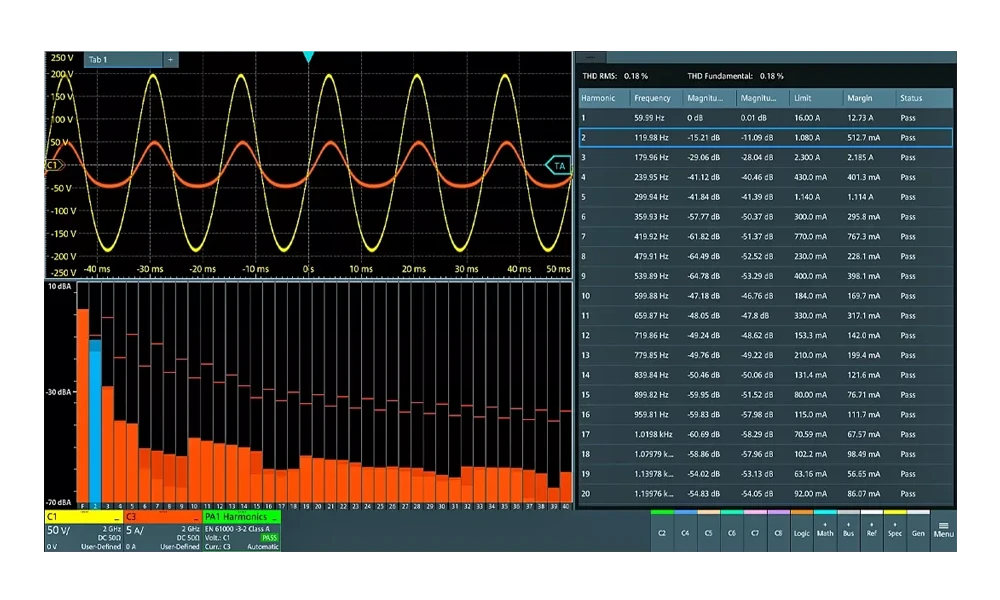

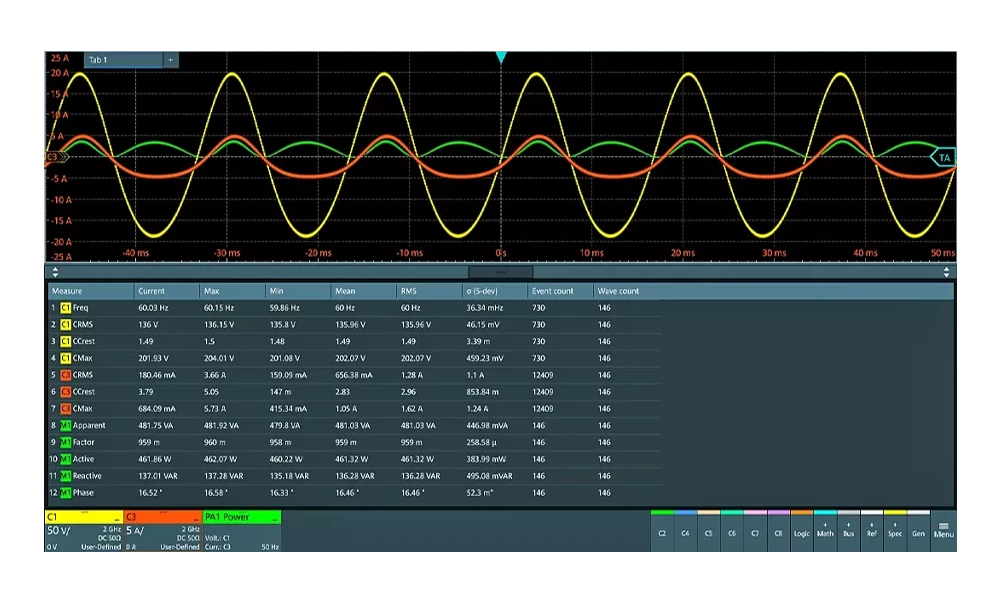

The analysis of harmonics and power factor is essential for evaluating energy efficiency.

The MXO Series combines voltage and current measurements using differential high-voltage probes and current sensors.

Fig. 4: Power analysis with current and voltage waveforms – phase relationship and power factor. Thanks to the high-definition mode, power losses can be identified in real time.

Measurement results can be correlated over long periods, for example to investigate charging cycles or driving profiles.

With up to eight analog channels, MXO oscilloscopes are ideal for use in electric drive systems.

They can simultaneously capture:

Fig. 5: Simultaneous acquisition of three-phase currents, three-phase voltages, and sensor signals.

This provides a complete, synchronized picture of both the electrical and mechanical system behavior – the foundation for in-depth optimization.

The demands placed on measurement systems in e-mobility continue to rise:

Higher switching frequencies, increasing power densities, and more complex control algorithms require tools with high resolution, speed, and intelligence.

With the MXO Series, Rohde & Schwarz delivers an oscilloscope platform that fully meets these requirements.

The new MXO3 further extends these capabilities – featuring a compact design, improved user interface, and enhanced analysis functions for future generations of electric drives.

dataTec already provides reference systems that seamlessly integrate MXO technology – supporting research, development, and quality assurance in modern drivetrain systems.

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.