#statusMessage#

Do you want to start the comparison now?

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cause fires. With automated FLIR thermography, you can detect thermal anomalies at an early stage – before damage or safety risks arise. Whether in battery production, mechanical engineering or energy supply: Thermography creates transparency and certainty of action.

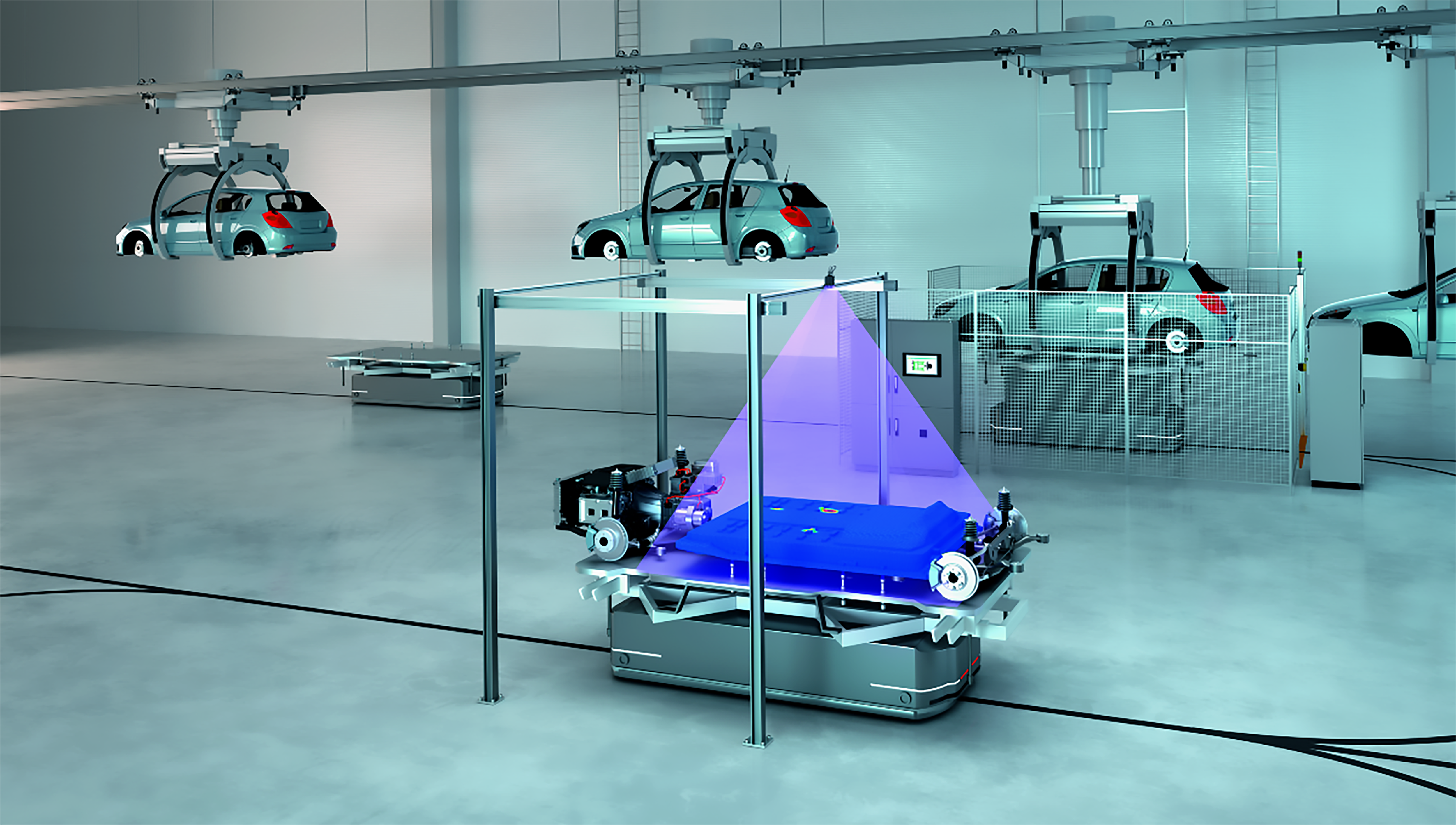

Modern production lines must run efficiently, stably and reliably – around the clock. But many sources of error remain invisible: overheated components, uneven heating, faulty welded joints or potential fire hazards.

FLIR thermal imaging cameras provide precise temperature data in real time – contactless, reliable and fully integrable into your automation environment. This increases system availability, reduces your maintenance costs and improves safety and product quality at the same time.

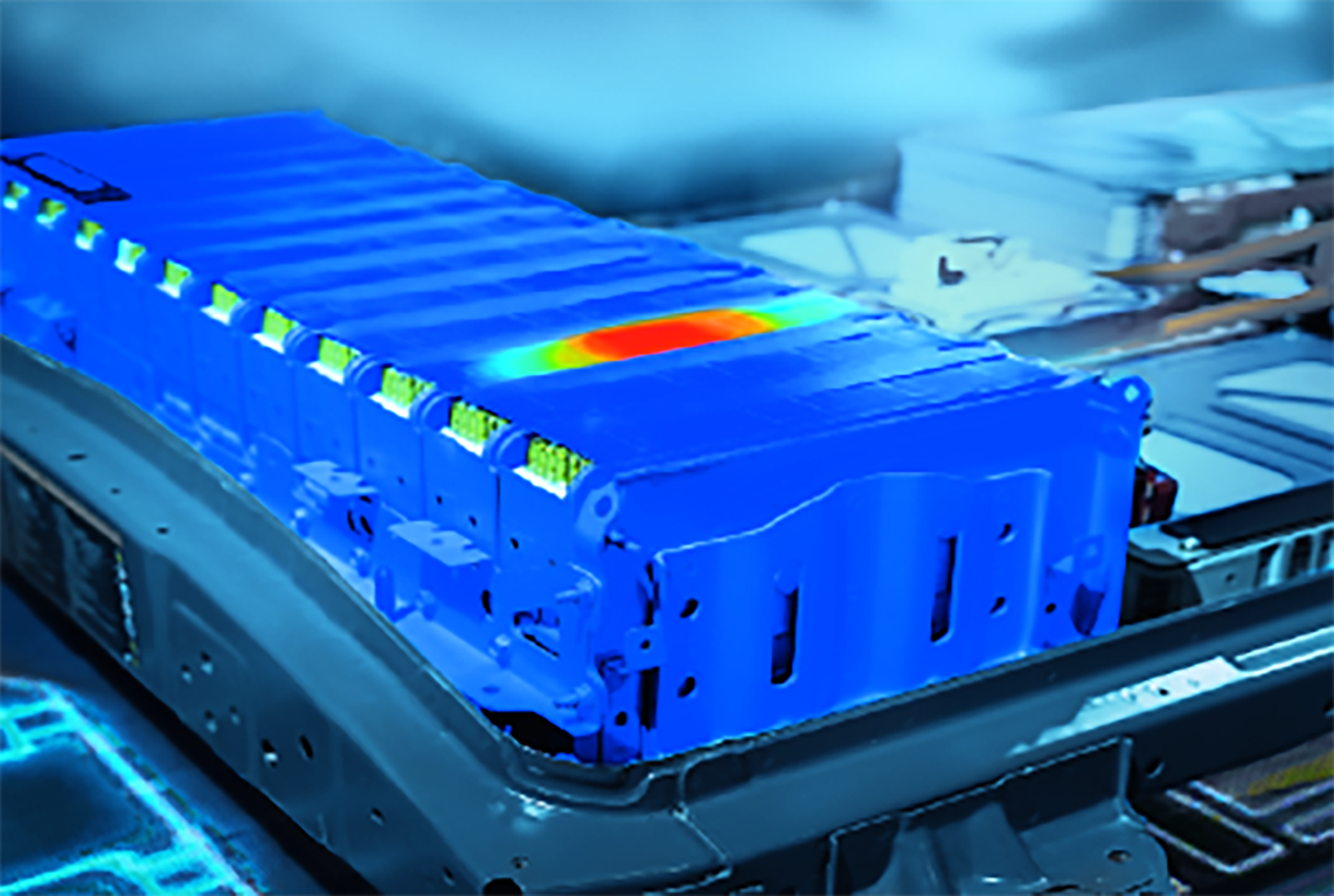

Lithium-ion batteries are powerful, but thermally demanding. Even the slightest overheating on cell surfaces, connectors or cooling systems can be a harbinger of a thermal runaway, a dangerous chain reaction in which cells ignite.

With FLIR thermal imaging cameras, you can monitor batteries continuously, contact-free and with high precision. Critical developments are detected at an early stage, safety reactions are automated and fires are prevented.

Recognize risks before they become a danger.

FLIR thermography is a powerful tool for preventive safety. It not only supports maintenance, but also active fire protection, risk assessment and safety management. This is done contactless, continuous and documentable.

| Industry | Typical applications |

|---|---|

| Automotive industry | Weld seam inspection, battery monitoring (e.g. e-mobility) |

| Food & Packaging | Sealing seam testing, temperature control for thermal processes |

| Electrical engineering | Hotspot detection in control cabinets and circuit boards |

| Mechanical & plant engineering | Thermal monitoring of motors, bearings and drives |

| Energy supply | Temperature control in transformers and distribution units |

| Battery production & storage | Monitoring of storage cells, second-life applications and cooling processes |

| Recycling & logistics | Fire protection during transportation, storage and disassembly of lithium-ion cells |

Scalable thermography – from cost-efficient entry-level solutions

to powerful high-end variants.