#statusMessage#

Do you want to start the comparison now?

#statusMessage#

Do you want to start the comparison now?

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Disturbances in the power grid often go unnoticed until systems shut down or equipment fails. Regular power quality asse...

In this practical checklist you will learn how to calibrate your measuring and test instruments effectively – simply, ef...

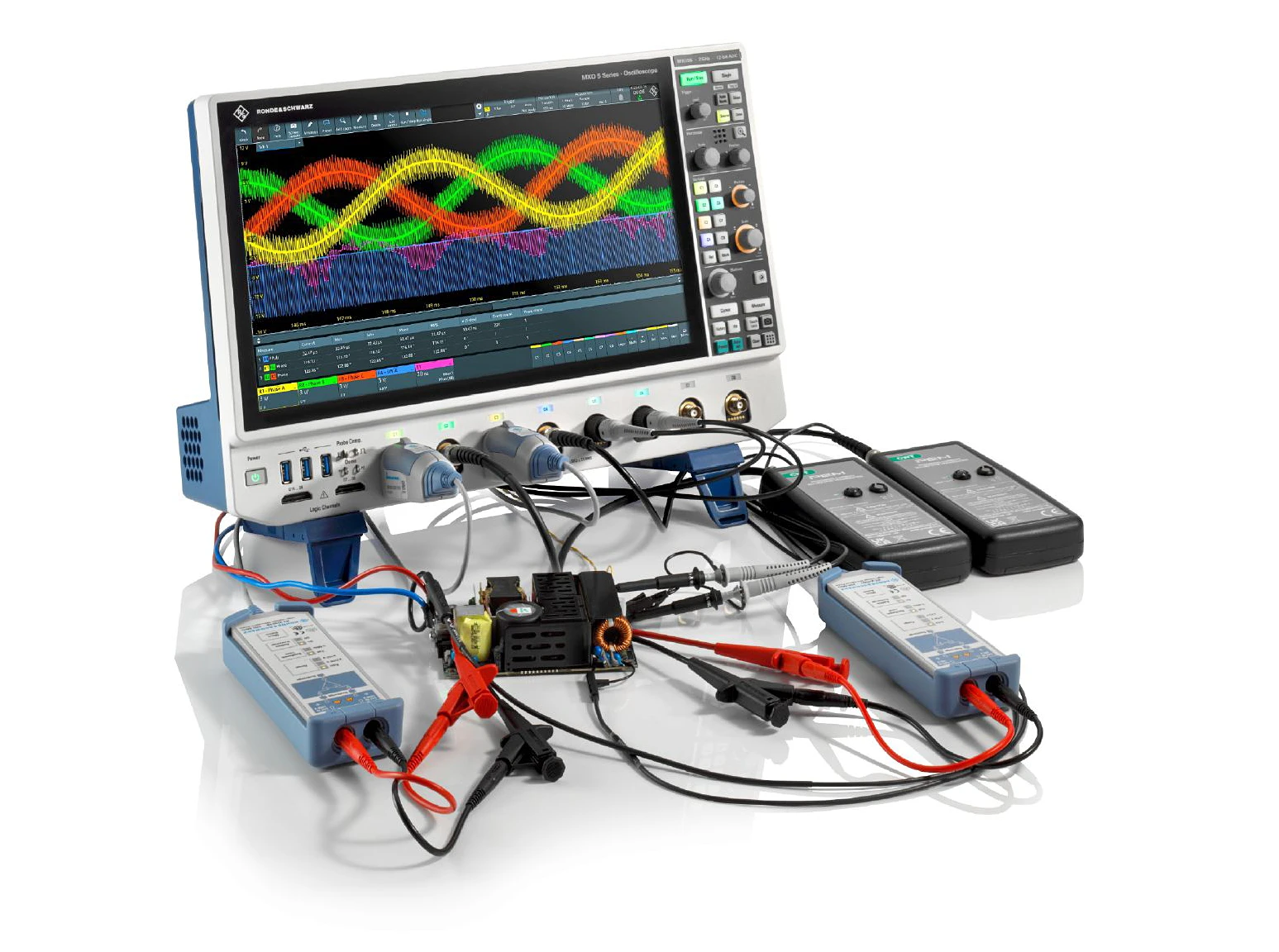

Modern oscilloscopes of the MXO Series from Rohde & Schwarz enable precise analysis and optimization of electric drivetr...

Manufacturer number: FLUKE-TC01C 25 HZ

| Dimensions (L x W x H) (mm): | 60 x 34 x 11 |

|---|---|

| Focus: | Fixed focus |

| Frame rate (Hz): | 25 |

| Image memory: | no |

| Max. field of view (FOV): | 56° x 42° |

| Resolution in pixels: | 256 x 192 |

| Smallest resolution IFOV (mrad): | 3.81 |

| Temperature measuring points: | 49,152 |

| Temperature measuring range: | -20°C to +550°C |

| Thermal sensitivity (mK): | 50 |

| Weight (kg): | 0.13 |

The Fluke iSee series (TC01A / TC01B / TC01C) transforms your smartphone into a powerful thermography tool: Simply connect via USB-C or Lightning, start the app and immediately measure temperatures and record thermal images and videos. The series is designed for electrical and mechanical testing, HVAC inspections, research & development, maintenance and quality control and significantly increases the efficiency of inspections.

Despite the ultra-compact format, the series delivers a detailed thermal image quality with 256 x 192 pixels resolution, a thermal resolution and a thermal resolution;resolution, a thermal sensitivity (NETD) of 50 mK and a measurement accuracy of ± 2 % or ± 2 °C (depending on which value is greater). With a temperature range up to 550 °C, the camera is suitable for many typical industrial and service applications.

&p>Professional analysis functions are available via the Fluke iSee app: Point, line and area measurements, real-time temperature alarms, time-lapse operation for unattended imaging, adjustable emissivity, and the ability to contrast thermal and visual images for locating, comparing and archiving. More than 10 standard or user-defined color palettes facilitate the interpretation of thermal images.

The Fluke iSee series is suitable for inspections of control cabinets, motors, fans, circuit boards, underfloor heating, air conditioning outlets, electrical switches and for outdoor inspections.

The Fluke TC01C is designed for use with iPhone and iPad with USB-C connection and is connected directly to the iOS device via the USB-C interface. With a refresh rate of 25 Hz, it offers a very smooth and detailed display of thermal images and is ideal for dynamic inspections, moving objects and fast scanning processes.

Technically, the TC01C offers the same professional performance data as all models in the series: A resolution of 256 x 192 pixels, a large temperature measurement range up to 550 °C, a high thermal sensitivity of 50 mK and precise temperature measurement with ± 2% or ± 2 °C. Thanks to the direct USB-C connection to modern iOS devices, it is particularly future-proof and convenient to use.

The TC01C is functionally on a par with the TC01B and TC01A (25 Hz). Compared to the TC01B, it differs in that it has a USB-C connection instead of Lightning and is therefore aimed at current iPhone and iPad generations. Compared to the TC01A (9 Hz), it offers a significantly higher refresh rate and a visibly smoother display. The TC01C is the optimal choice for iOS users who rely on modern USB-C connectivity.

Differences within the series:

TC01C: USB-C, iOS, 25 Hz.

TC01B: Lightning, iOS, 25 Hz.

TC01A (25 Hz): USB-C, Android & HarmonyOS, 25 Hz.

TC01A (9 Hz): USB-C, Android & HarmonyOS, 9 Hz – cost-efficient variant for standard applications.

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Discover our selection of intrinsically safe multimeters, pressure calibrators, milliohmmeters, thermal imaging cameras ...

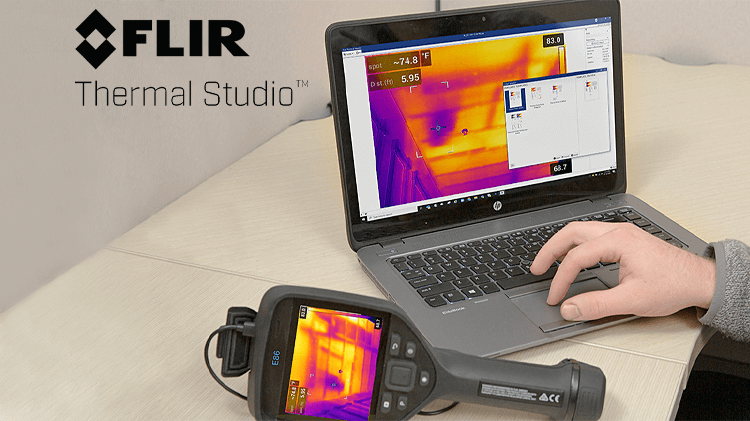

In order for the inspection of buildings and systems to lead to decision-relevant information, the precise evaluation of...

In the second episode of dataTec unboxed, we present the Ex Pro thermal imaging camera series from FLIR. Discover suit...

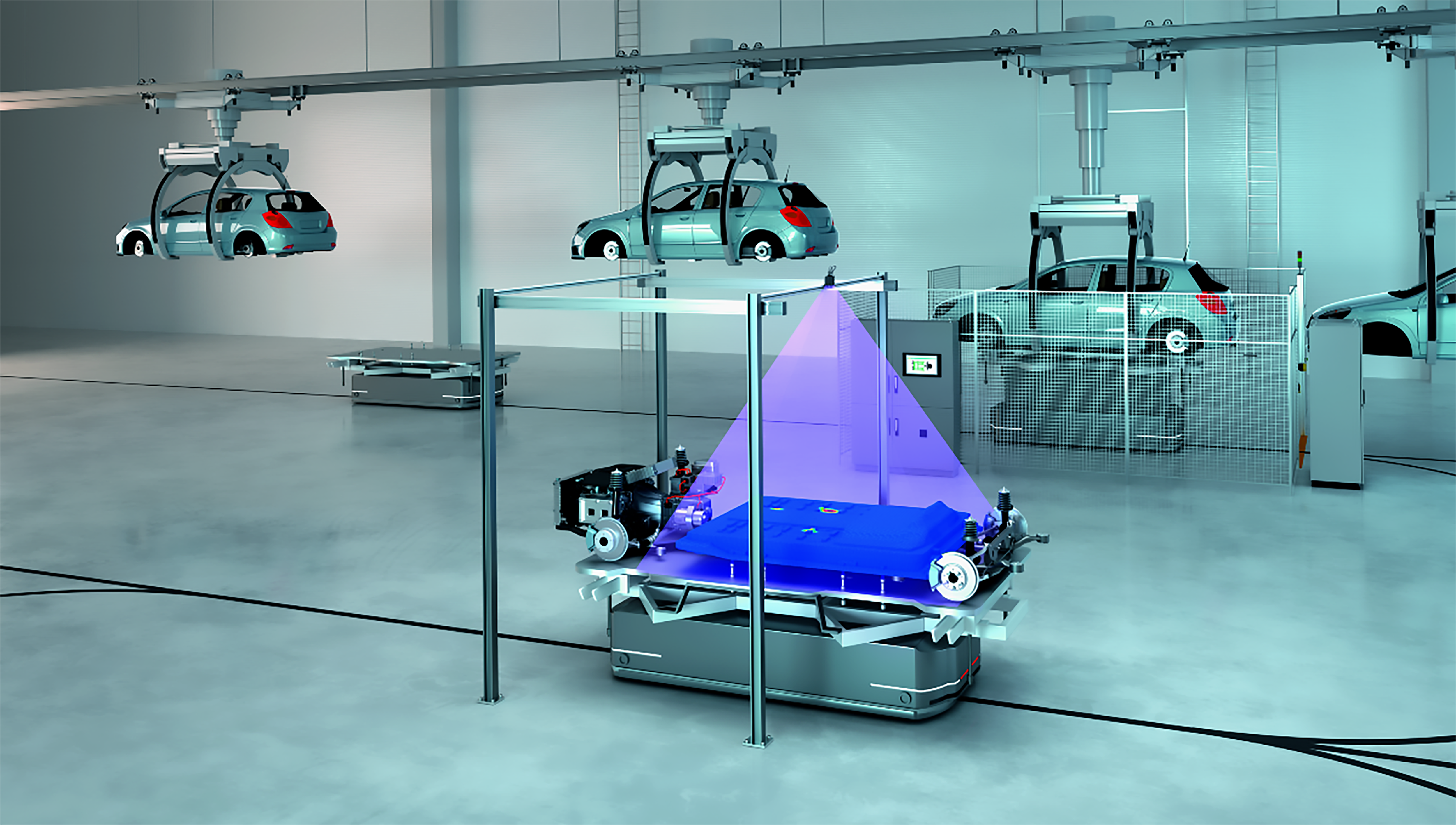

Automation with thermal imaging technology has proven to be a reliable solution for quality control in various industrie...

Thermal imaging cameras are quickly ready for use and easy to operate – directly on site: for example in buildings or pr...