#statusMessage#

Do you want to start the comparison now?

#statusMessage#

Do you want to start the comparison now?

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Disturbances in the power grid often go unnoticed until systems shut down or equipment fails. Regular power quality asse...

In this practical checklist you will learn how to calibrate your measuring and test instruments effectively – simply, ef...

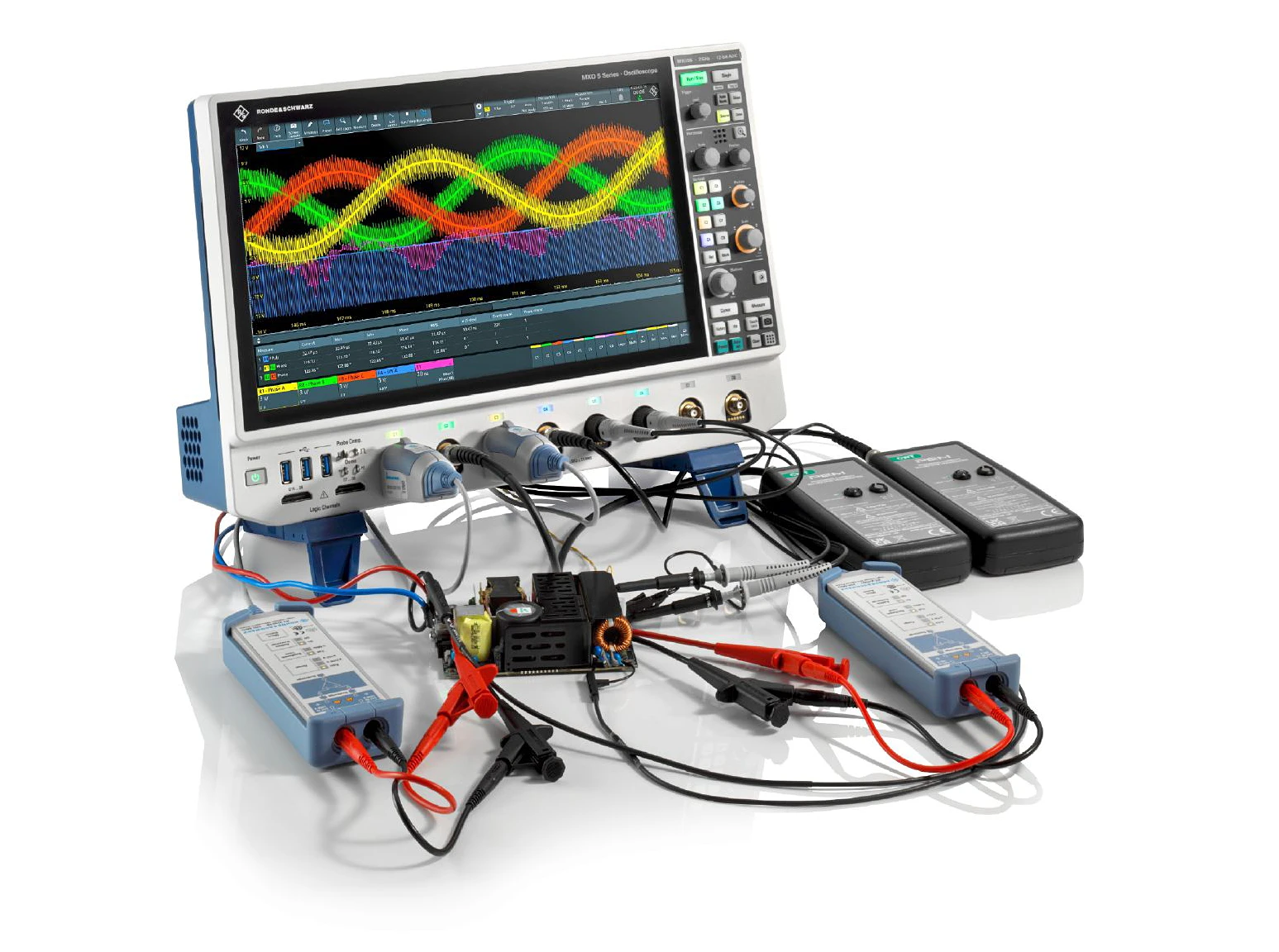

Modern oscilloscopes of the MXO Series from Rohde & Schwarz enable precise analysis and optimization of electric drivetr...

Manufacturer number: 91902-0202

Further technical data of the FLIR A400 can be found in the attached data sheet.

| Article number: | 91902-0202 |

|---|---|

| Dimensions (L x W x H) (mm): | 138 x 77 x 77 |

| Focus: | autofocus |

| Frame rate (Hz): | 30 |

| Image enhancement technology: | MSX |

| Image memory: | No |

| Integrated viewfinder: | No |

| Interchangeable lenses: | Yes |

| Interfaces: | Ethernet |

| Max. field of view (FOV): | 24° x 18° |

| Model: | A400 24° Standard Science Kit |

| Resolution in pixels: | 320 x 240 |

| Smallest resolution IFOV (mrad): | 1.31 |

| Temperature measuring points: | 76,800 |

| Temperature measuring range: | -20°C to +1500°C |

| Thermal sensitivity (mK): | 40 |

| Warranty (years): | 2 |

| Weight (kg): | 2 |

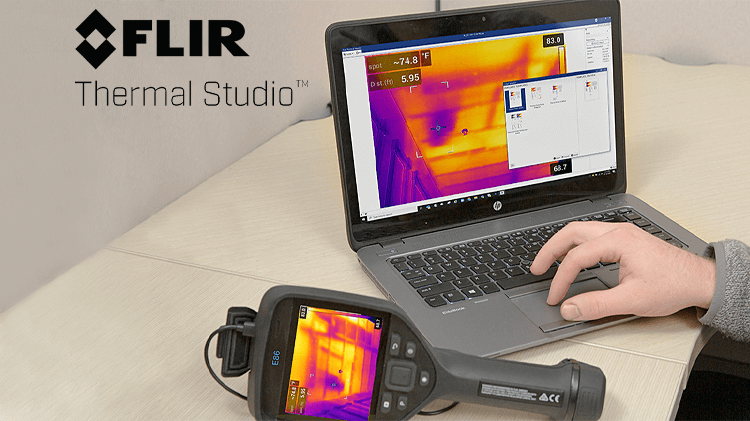

The thermal imaging cameras of the FLIR A400 / A700 Science Kits are characterized by precise thermal image data. The cameras offer simplified connectivity, precision and meaningful data, which engineers and researchers alike are enthusiastic about. This camera series is suitable, among other things, for checking components, product development and error analysis, but also for numerous other applications in research.

The FLIR A400 is an intelligent thermal imaging camera which is required for complex surveillance systems. The holistic configuration is used in a wide variety of areas, for example in product quality control or in the monitoring of critical infrastructure. The automation camera can be configured for the most complex remote monitoring, alarm and analysis applications and can be integrated and operated in HMI / SCADA systems.

No matter how you use the FLIR A400, the interaction of the various components is convincing in many scenarios. The motor-driven focus control and the connectivity of the thermal imaging camera offer unprecedented convenience. The 24-degree lens of the standard set offers a huge field of view from which research and development applications benefit enormously.

The configuration options of the camera are flexible. It is thus possible to adapt the quality and safety requirements to your needs. The different alarms and measuring tools for the respective variations support an analysis that is still being carried out in the device, so that the results are available to you almost in real time.

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Discover our selection of intrinsically safe multimeters, pressure calibrators, milliohmmeters, thermal imaging cameras ...

In order for the inspection of buildings and systems to lead to decision-relevant information, the precise evaluation of...

In the second episode of dataTec unboxed, we present the Ex Pro thermal imaging camera series from FLIR. Discover suit...

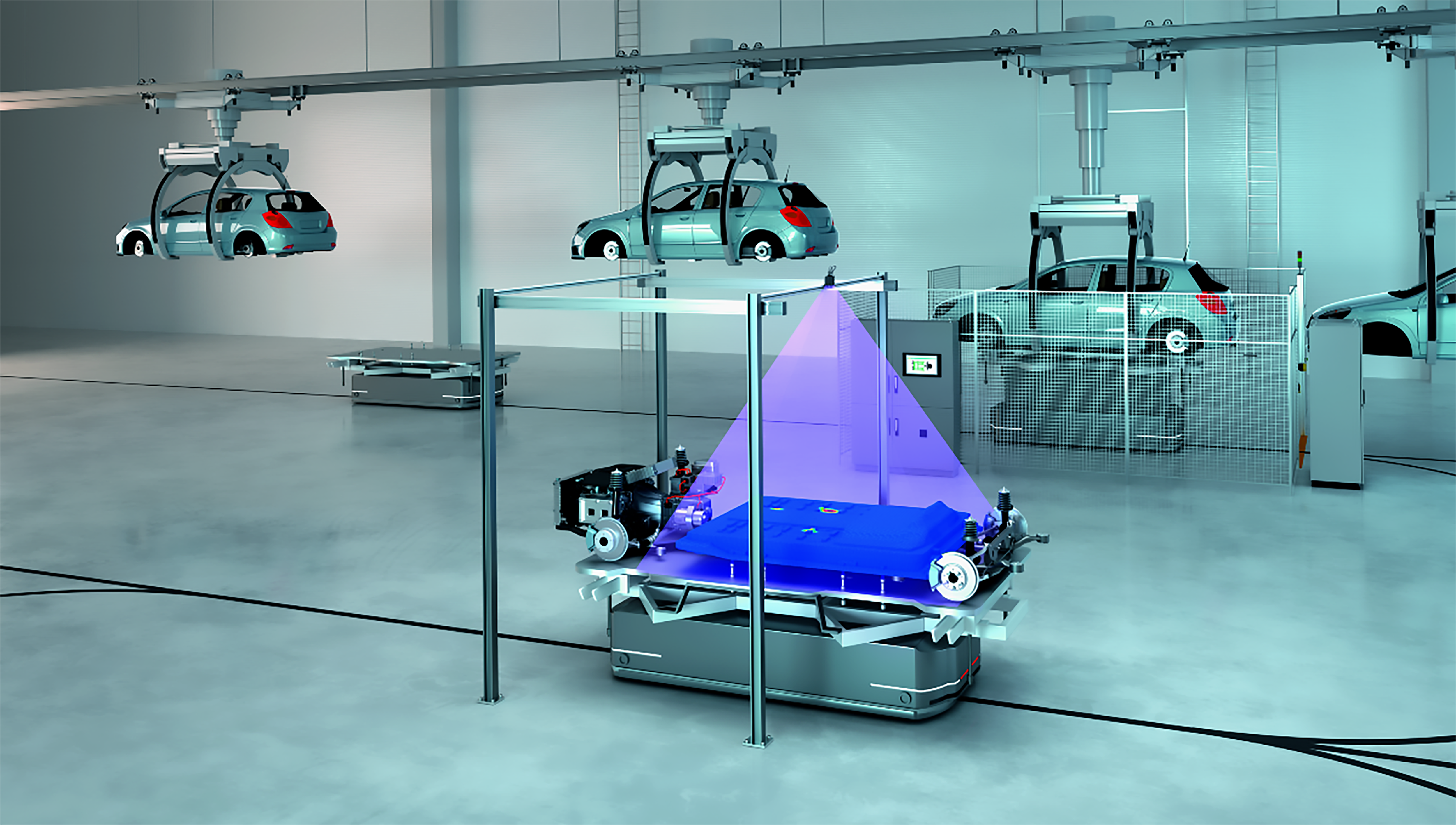

Automation with thermal imaging technology has proven to be a reliable solution for quality control in various industrie...

Thermal imaging cameras are quickly ready for use and easy to operate – directly on site: for example in buildings or pr...