#statusMessage#

Do you want to start the comparison now?

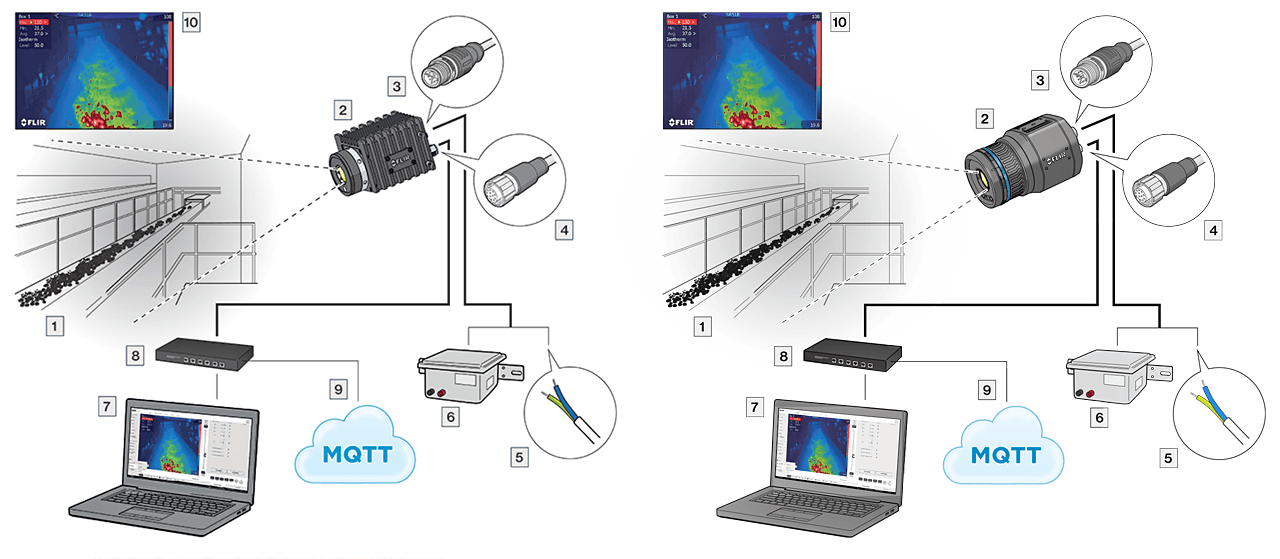

The fixed thermal cameras are ideal for customers who require simple, integrated analysis functions and temperature-based measurement tools that transmit data via standard protocols to industrial control and monitoring networks. Simplified integration is enabled through intelligent thermal sensors that communicate with industrial standard protocols and video management systems – allowing easy HMI and SCADA integration with common industrial protocols and alarm I/O.

Targets are easier to identify using MSX® image enhancement, which overlays scene details from the optionally integrated digital camera onto the full thermal image. Alternatively, FSX® image optimization technology (Flexible Scene Enhancement) enhances contrast in areas with similar temperatures and highlights structural details under low-light conditions. Additionally, the models comply with IP54 or IP66 protection ratings to withstand harsh environmental conditions.

The A50 and A70 cameras with Smart Sensor are ideal for users who want integrated, camera-based analysis and alarm functions for condition monitoring and early fire detection. With options for Wi-Fi, an integrated visual camera, and ONVIF S compatibility, the A50/A70 cameras provide a flexible, configurable solution that meets the individual requirements of automation customers across various industries.

When used as a system component for Cloud and Industrial Internet of Things (IIoT) solutions, the A50/A70 cameras can help companies protect assets, improve safety, maximize uptime, and minimize maintenance costs.

The A400, A500, and A700 thermal cameras with Smart Sensor offer advanced thermal imaging combined with network-based data processing and Industrial IoT connectivity, simplifying integration into new or existing networks. The motorized precision focus enhances temperature measurement accuracy for both near and distant objects. With multiple field-of-view options and unparalleled network connectivity, these automation cameras are suitable for the most complex remote monitoring, alarm, and analysis applications.

Automation solution providers receive a camera that is easily integrated, configured, and operated within HMI/SCADA systems. These cameras can therefore be applied to a wide range of tasks, such as monitoring critical infrastructure, assessing product quality, or detecting early signs of excessive heat.

When considering the deployment of thermal cameras as part of an automation application, several factors must be considered. Start the configuration by selecting the following criteria:

1. Camera Model.

2. Image Streaming Configuration.

3. Suitable Optics (only possible/required for Axxx).

T300239; IR lens, f=10 mm (42°)

Wide-angle lens capturing the largest field of view for imaging buildings, roofs, or other areas where capturing maximum information in a single frame is critical.

T300240; IR lens, f=17 mm (24°)

Often considered the “standard lens.” With a 24° × 18° field of view, users can maintain a safe distance from live equipment (e.g., 3 m) while still resolving smaller objects sharply.

T300241; IR lens, f=29 mm (14°)

Telephoto lens with a narrow field of view for precise focus and sharp images of distant objects.

T300586; IR lens Dual FOV, f=17/29 mm (24°/14°)

FlexView™ DFOV (dual field-of-view) lens with two fields of view: the wider 24° view allows broad area scanning for potential anomalies, while the narrower 14° view provides higher resolution through a 2.8× optical zoom with more pixels on the target object. Switching is software-controlled.

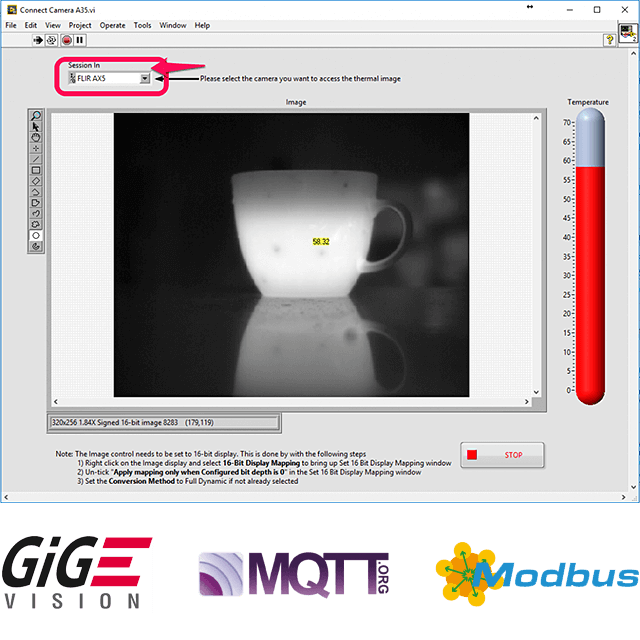

4. Analysis Software.

FLIR automation cameras integrate easily with your preferred analysis software. They are currently compatible with Cognex Designer Pro, NI Software, Pleora eBUS, Teledyne, and Spinnaker SDK.

5. Define Target Areas and Alarm Settings.

Identify critical zones to monitor for hotspots or temperature fluctuations. FLIR cameras allow selection of up to 10 target areas. Using the web-based configuration interface on a mobile device or computer, measurement points can be selected, measurement areas drawn, or custom areas created. Define your alarm parameters and desired response by specifying the output type of the data acquisition.

6. Integrate into Control Processes.

For improved intervention, integrate thermal automation cameras into other control processes. Verify that your automation camera is compatible with communication protocols such as GigE Vision, RTSP, MQTT, RESTful API, MODBUS TCP & Master, Ethernet/IP, or FTP.

Are you still uncertain or do you have further questions regarding the instruments? Do not hesitate to contact us. Whether directly by phone or conveniently via an online demo right at your screen – our experts are here for you.