#statusMessage#

Do you want to start the comparison now?

Signals – whether analog, digital, or complexly modulated – serve as the central link between sensors, control systems, and actuators. In our article, you will learn how process signals are characterized, the role arbitrary function generators play in signal generation, and which solutions leading manufacturers offer for this purpose. Immerse yourself in the world of industrial signal technology and discover how to make your applications reliable and future-proof – read on now.

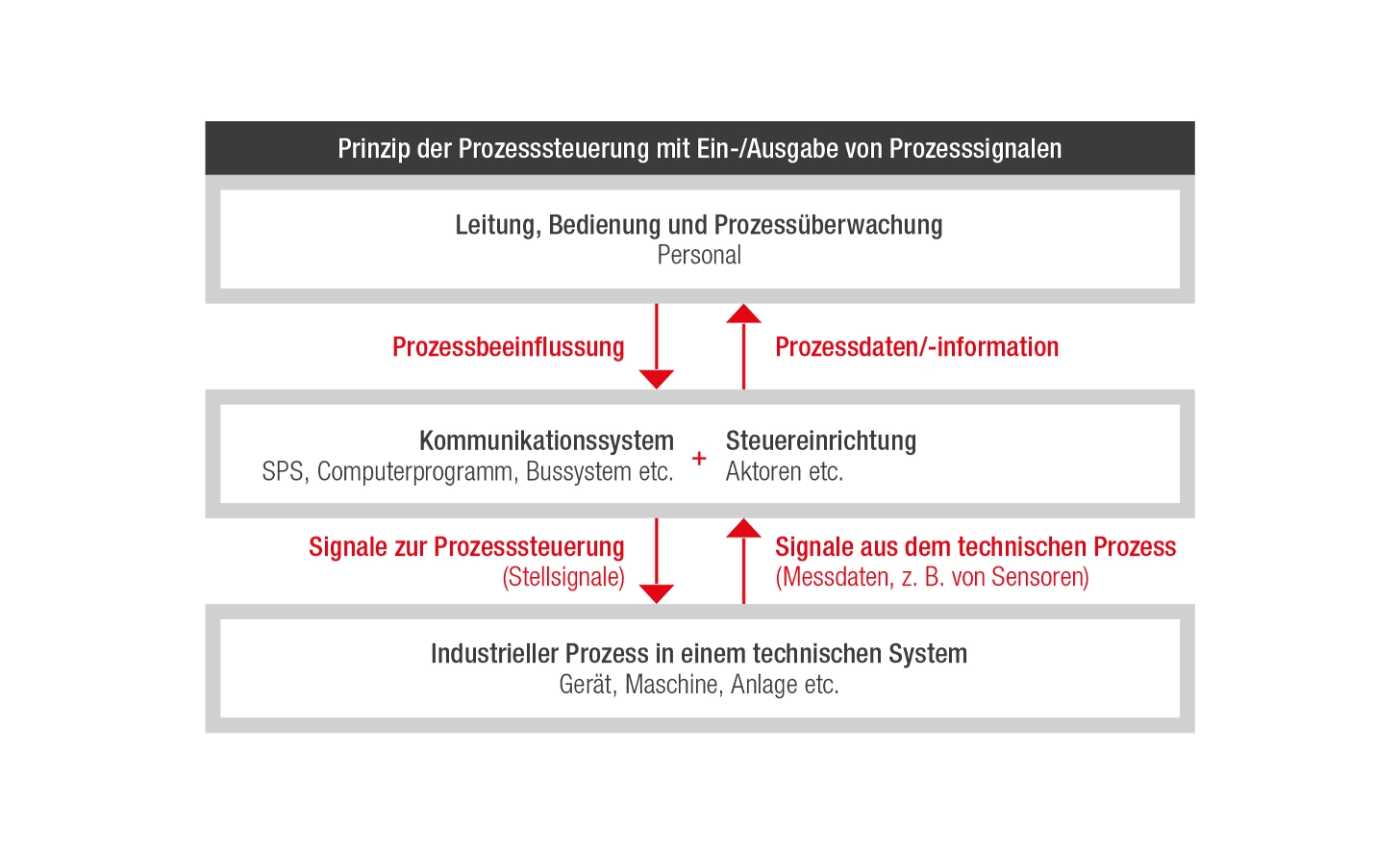

Industrial processes are based on the input and output of process signals. These are defined by corresponding input and output parameters, such as flow, pressure, or temperature values. A signal or signal waveform (e.g. sine, pulse) is derived from a physical quantity. In process engineering, such signals are used in the form of voltage levels or power variations.

The electrical parameter of a signal represents the information parameter, specified in units such as volts or amperes. The physical quantity converted into the electrical parameter is the signal carrier, e.g. electrical voltage/current, temperature, or fill level.

In automation and process engineering, process control typically focuses not only on the operation of the process itself but also on specific safety aspects. The control of process equipment, such as actuators, therefore requires a combination of process data and safety data — or a combination of the corresponding signals.

(Chart only in German)

Analog signals

Defined by amplitude, frequency, and phase

Digital signals

Control signals for switches, etc.

Pulse signals

Speed sensors (e.g. rotary encoders)

Edge-triggered signals

State transition of a process parameter

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.