#statusMessage#

Do you want to start the comparison now?

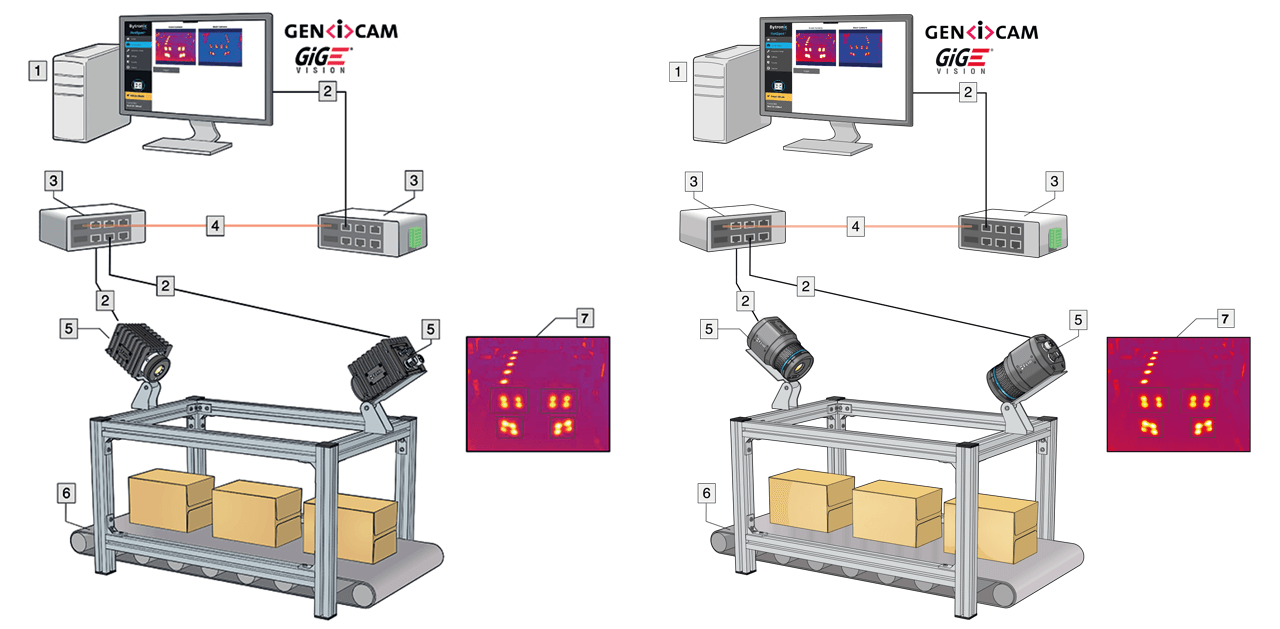

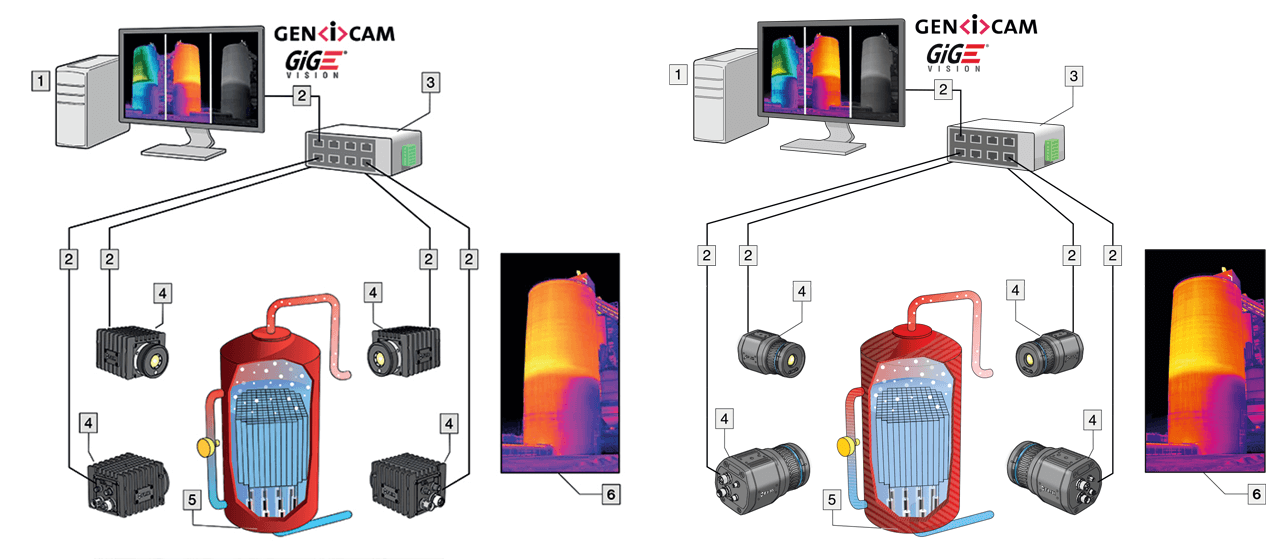

The fixed thermal automation cameras are ideal for customers who need to perform complex image analyses using their own machine vision software and assist manufacturers in optimizing process control and quality assurance. Simplified integration is achieved through non-proprietary industrial standard connectivity, data and image streaming, and camera control – GigE Vision- and GenICam-compatible for camera control and thermal/visual image-video streaming in third-party machine vision applications. Targets can be more easily identified through optional simultaneous streaming of thermal and conventional digital images with a single camera using MSX image enhancement. Alternatively, FSX® (Flexible Scene Enhancement) image optimization technology improves contrast in areas with uniform temperatures and highlights structural details under low-light conditions. Additionally, the models meet IP54 or IP66 ingress protection ratings to withstand harsh environments.

The A50 and A70 image-streaming cameras are the ideal choice for users who require camera control and image-streaming capabilities over Ethernet, along with the flexibility to perform analyses and capture raw data of thermal features using preferred software applications. Thermal resolution and ±2 °C accuracy support production or QA processes to optimize production settings and product quality.

With options for Wi-Fi, an integrated visual camera, compressed radiometric image streaming, and ONVIF S compatibility, these compact, lightweight, fixed-focus automation cameras enhance process control and quality assurance, improving yield, product quality, and throughput while reducing costs.

The Axxx series image-streaming cameras provide the monitoring capabilities needed for accurate detection and identification of thermal issues in manufacturing and industrial processes. With multiple field-of-view options, multi-streaming functionality, motorized focus control, and optional compressed radiometric streaming over Wi-Fi, these fixed camera solutions can handle even the most complex remote monitoring tasks.

Optimize process control and improve quality assurance through integrated thermal inspections, or detect abnormal conditions before a fault causes unplanned downtime in your production facility. The Axxx series also enables early detection of potential fires, allowing faster initiation of firefighting measures and minimizing injuries and property damage. This significantly improves product quality, productivity, maintenance, and safety.

When considering the deployment of thermal cameras as part of an automation application, several factors must be considered. Start the configuration by selecting the following criteria:

1. Camera Model.

2. Image Streaming Configuration.

3. Suitable Optics (only possible/required for Axxx).

T300239; IR lens, f=10 mm (42°)

Wide-angle lens capturing the largest field of view for imaging buildings, roofs, or other areas where capturing maximum information in a single frame is critical.

T300240; IR lens, f=17 mm (24°)

Often considered the “standard lens.” With a 24° × 18° field of view, users can maintain a safe distance from live equipment (e.g., 3 m) while still resolving smaller objects sharply.

T300241; IR lens, f=29 mm (14°)

Telephoto lens with a narrow field of view for precise focus and sharp images of distant objects.

T300586; IR lens Dual FOV, f=17/29 mm (24°/14°)

FlexView™ DFOV (dual field-of-view) lens with two fields of view: the wider 24° view allows broad area scanning for potential anomalies, while the narrower 14° view provides higher resolution through a 2.8× optical zoom with more pixels on the target object. Switching is software-controlled.

4. Analysis Software.

FLIR image-streaming cameras can be integrated into various analysis software solutions. For example, into Teledyne FLIR Research Studio for evaluating multiple streams simultaneously in research and development, or into machine vision software such as DALSA iNspect Express or NI Vision for automating machine processes.

5. Define Target Areas and Alarm Settings.

Region Of Interest (ROIs) are defined and analyzed within the software solution. Depending on the application, this can accompany a development process or monitor a production step.

Are you still uncertain or do you have further questions regarding the instruments? Do not hesitate to contact us. Whether directly by phone or conveniently via an online demo right at your screen – our experts are here for you.