#statusMessage#

Do you want to start the comparison now?

Anyone who wants to launch a new product on the market today must ensure that it meets the highest quality standards. Otherwise, the manufacturer may be left with the development costs because the product does not sell as desired - or is rejected by the client. This applies to the coloring of a new chewy sweet, which must not fade in the light, as well as to the suitability of plastic packaging as an alternative outer packaging for beer; for the corrosion-resistant façade of a high-rise building in Dubai or the material resistance of a new vehicle part in extreme weather conditions.

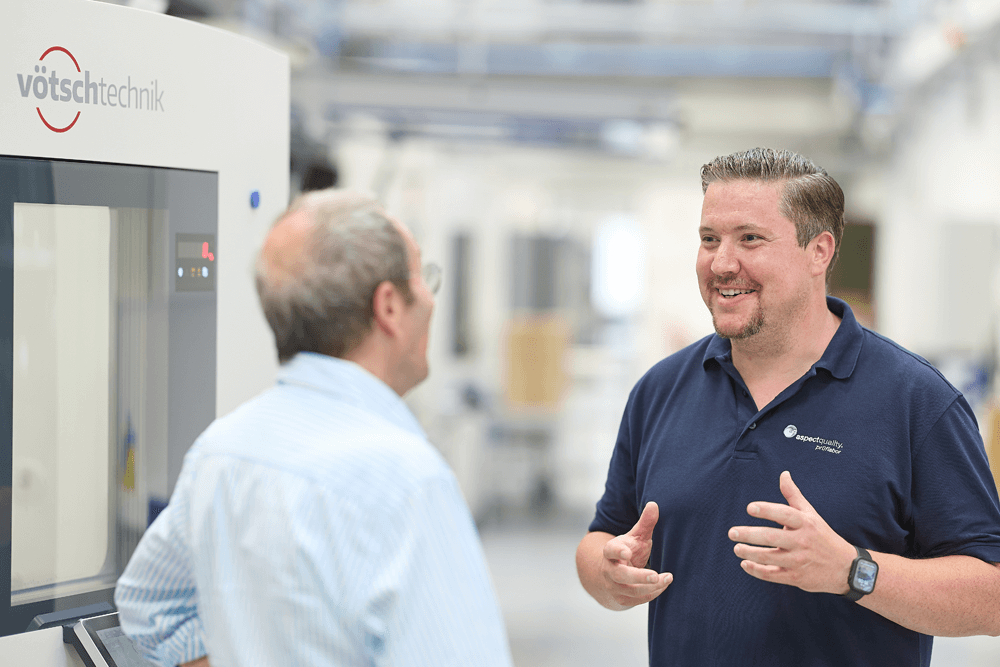

The aspect quality test laboratory in Reutlingen specializes in putting these and other materials through their paces. The company obtains measuring and testing equipment from dataTec.

Heiko Walter | aspect quality GmbH

„We are environmental simulators“, says Heiko Walter with a grin. „In our industry, that's what we jokingly call a test laboratory that simulates environmental conditions.“ And that is precisely the specialty of aspect quality GmbH in Reutlingen. Managing Director Markus Theurer founded the company in 2006. aspect quality quickly made a name for itself as an independent technical testing laboratory and specialist in environmental simulation. A topic that enjoys high priority, especially among car manufacturers whose vehicles have to function reliably in all regions of the world.

Business flourished, and in 2012 Heiko Walter joined the team as the second Managing Director. He had previously worked in product development at an automotive supplier and had used aspect quality's services in this role. „I knew Markus and the work of his company quite well and found it exciting to join,“ he says.

Today, aspect quality GmbH has 15 employees. Their job is to expose a wide variety of products and materials to extreme environmental conditions and document how this rough treatment affects them. Do they become brittle or soft? Do they change shape or color, and if so, at what point is their functionality impaired beyond what is tolerable? Do they still fulfill their purpose at all after the test procedure? And, and, and…

„As a rule, we receive products or materials for testing that are still under development. For example, A, B and C samples that need to be approved before they go into series production. But of course we also test products that are already in series production – for example in the form of the annual requalification test – or we are involved in complaints to check the extent to which any material defects are the reason for the complaint.“

The test scenarios are as varied as the environmental conditions that prevail on earth. There are test chambers in which temperature shock tests are carried out - for example, 130°C at the top and sub-zero temperatures (e.g. -40°C) at the bottom. The product to be tested is repeatedly moved from the upper to the lower area and back again within seconds.

Or solar simulation tests. „We create irradiation conditions comparable to those at the equator, not only in terms of heat, but also in terms of the light spectrum. With the emitters used, this is almost identical to the radiation spectrum of our sun.“

To test whether or how quickly a material corrodes, it is subjected to an alternating corrosion test or salt spray, for example. aspect quality's equipment also includes devices and test chambers for mechanical stress tests or abrasion tests.

In short: there is hardly a load situation that the Reutlingen test laboratory cannot simulate. „We work with temperatures as low as minus 70 degrees and as high as plus 650 degrees Celsius,“ explains Heiko Walter. „These are extreme conditions“

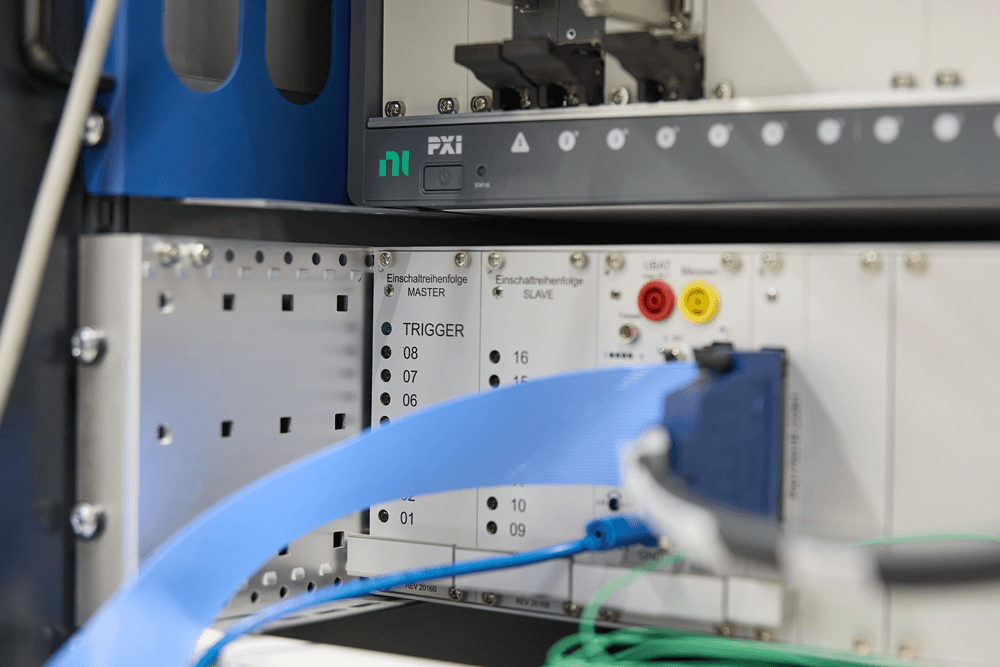

Of course, it is important that the conditions in the test chambers are stable and correspond to what is required for the tests. It is also important to meticulously measure and document the changes to the workpieces. „After all, our job is to find out how the materials and products behave under the respective conditions.“ To do this, the test specimen is fitted with sensors whose data is recorded, processed and documented by the measuring and testing devices outside the chamber.

And this is exactly where dataTec comes into play. For example, aspect quality obtains data loggers from its Reutlingen-based technology partner, such as Graphtec and Keysight. Oscilloscopes, voltage testers and function generators, digital multimeters and thermal imaging cameras are also included, as are devices for testing electrical safety, insulation resistance measurement and high-voltage testing.

We want to know how important the proximity of dataTec's field service is. „Very important,“ says Heiko Walter. „Our top priority is to be able to help our customers even in time-critical situations. The proximity, customer focus and efficiency of dataTec are extremely helpful here. Even if we make use of training courses at the dataTec Academy or the calibration service, it is of course easier if the partner is only a few minutes away by car.“

The short distance to each other also helps when a difficult test situation needs to be discussed at short notice. „We often have to talk about measurement scenarios with products where we are obliged to maintain confidentiality. This means that we have to describe the scenario in a sufficiently flowery way so as not to give away any secrets – and yet in such a way that the dataTec experts can recommend the right solution. It's good to be able to sit down with the sales force spontaneously.“

They have been working with dataTec for a good ten years, says Heiko Walter, and the partnership is extremely pleasant and constructive. „Whenever we come to dataTec with a problem, we find a solution together. What more could you want?“

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.