#statusMessage#

Do you want to start the comparison now?

Quality assurance in consumer electronics is more complex than ever: stable power supplies are crucial for device reliability, while increasing interference from the power grid raises the demands on testing. In this article, you will learn how oscilloscope-based measurement solutions, automated test software, and realistic AC disturbance simulations can be used to precisely validate critical device parameters. We demonstrate, in practical terms, how failure risks can be identified at an early stage and how tests can be performed efficiently – from signal acquisition to documentation. Read on to discover how you can professionally optimize your test processes.

Electrical devices typically contain a switched-mode power supply (SMPS) that converts AC to DC. From smartphones to notebooks, from LED lamps to washing machines – switching power supplies are found in almost every device. At the same time, disturbances originating from the power grid are increasing, for example due to voltage fluctuations caused by renewable energy sources or the widespread use of energy-saving lamps. Fault-prone SMPS can shorten the service life of end devices.

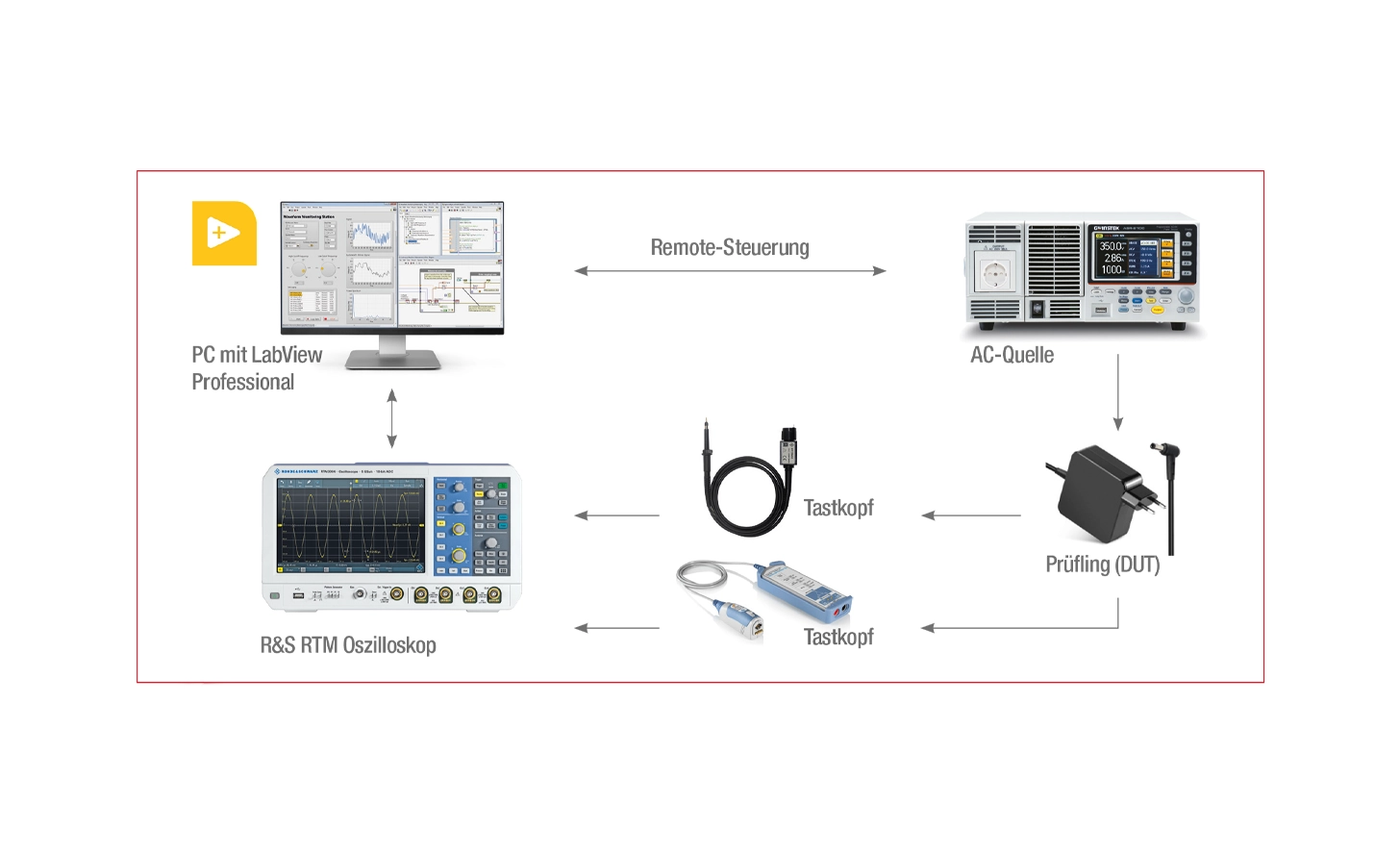

Thorough validation of these switching power supplies as part of quality assurance helps prevent device failures. The oscilloscope-based reference solution presented here enables the measurement of all performance-relevant parameters such as current, voltage, harmonics, transients, and power-on/off characteristics. The AC laboratory power source allows interference effects to be simulated for realistic operating conditions. Test execution can be easily automated using LabVIEW software.

The later a device fault is detected during development or production, the more costly it usually is to correct. To avoid worst-case scenarios such as system failures or product recalls, product defects should therefore be identified as early as possible.

Does the device under test (DUT) comply with the defined specifications?

Are the relevant EU directives and EN standards for electromagnetic compatibility (EMC) fulfilled?

How do the devices perform under real operating conditions, particularly in interaction with other components?

How can devices and components be tested efficiently and in compliance with applicable standards?

How can the required documentation and recording obligations be met?

(Chart only in German)

Verification of a power supply unit (= DUT) for consumer electronics is performed here using an RTM3000 Series oscilloscope from Rohde & Schwarz, together with suitable voltage probes (e.g. RT-ZHD16, RT-ZP05S) and current probes (e.g. RT-ZC03). The measurement procedure can be automated using NI LabVIEW Professional, which simplifies test execution and ensures consistent measurement results. The software controls both the oscilloscope for measurement and the AC power source, such as the ASR-2100 from GW Instek, which supplies the DUT and simulates electrical disturbances. The measurement results can be evaluated directly in LabVIEW.

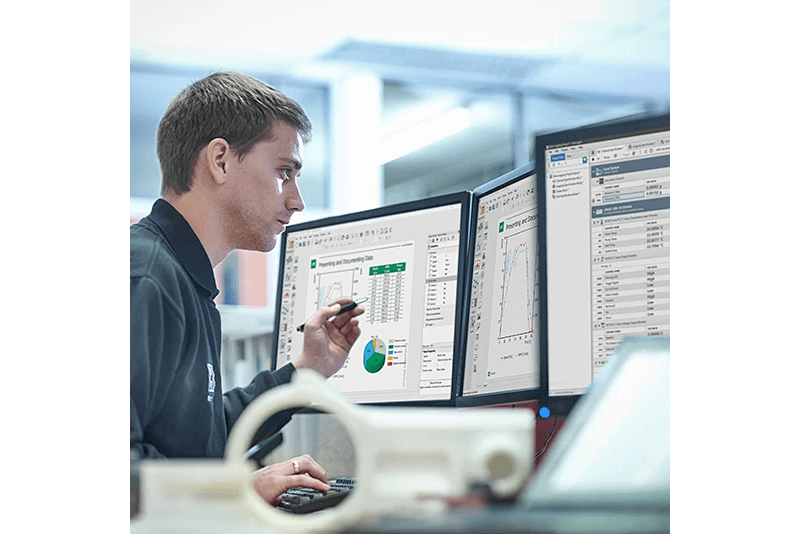

With LabVIEW, test engineers can rapidly develop automated validation and production test systems. Device configurations and measurement results are visualized, and errors can be corrected interactively. LabVIEW simplifies the development of data analysis routines and the integration of measurement hardware from any manufacturer.

Everything from a Single Source:

For your test application, dataTec provides the required measuring instruments and NI software products, as well as comprehensive training options.