#statusMessage#

Do you want to start the comparison now?

A visit to the iinovis company.

In the context of the energy transition, the topic of hydrogen is a real beacon of hope for many industries – but it is also fraught with uncertainty. Can fuel cells make the electric car the future of mobility? How safe is this technology? And is it economically viable? The company iinovis from Bad Friedrichshall in Baden-Württemberg has accompanied all developments in the automotive industry in its long company history. With a new facility for hydrogen system component testing, the company is now doing real pioneering work. We spoke to iinovis CEO Andreas Groß and Vice President Innovation Peter Diehl about why measurement and testing technology makes all the difference in testing.

Andreas Groß, CEO

Andreas Groß: It's always difficult not to fall into clichés. In industry, there are engineering service providers who offer to develop solutions for others – of course we do that too. What's special about iinovis is that we don't see ourselves as a personnel service provider and work on jobs for a few hours here or there. We want to develop innovative solutions together with our customers. We are also able to do more than just classic engineering. When it comes to testing or customised products, we have the technical, human and production resources to manufacture everything from parts and prototypes to entire vehicles. This involves not only large main series, but also special vehicles in limited quantities. We also supply complete wiring systems for high and low voltage.

Andreas Groß: The company has sold its expertise well in the past. But without innovation and transformation, you can no longer be successful in today's economic situation. Globalisation is hitting a country like Germany with high costs harder and harder. Very few people are still willing to pay for a development service for standard tasks if they can buy the service more cheaply on the international market. We need to move up a level here and become a driver of new developments. Think outside the box and do things differently, for example in the area of mobility. Some developments here will only really make themselves felt in 15 to 20 years' time. As a company, you also have to take your own employees with you.

Peter Diehl: As a company, we are currently investing heavily in innovation projects. We are moving away from what the customer commissions towards becoming a problem solver and consultant. This also includes investing in the knowledge of our own employees and ultimately in the knowledge of mankind in general – even if that sounds ambitious at first. The fact is that most of our innovation projects are subsidised. Hydrogen is a key area here. We take decarbonisation very seriously.

Peter Diehl, Vice President Innovation

Peter Diehl: Many start-ups appreciate our innovative and flexible approach. Large companies are very inflexible and have to focus on a lot of calculable day-to-day business. iinovis is the ideal size to be able to dedicate itself to new types of projects.

Andreas Groß: I like these 'visionary' projects. A customer comes and says they don't like the bodywork. And then they want us to convert five cars. We gain an incredible amount of new expertise from such projects. Someone else might want a new seat, but then more questions come up. We also 'annoy' our customers from time to time and encourage them to make lasting changes. As a result, we sometimes feel like a start-up ourselves. This spirit is fun and motivates us.

Peter Diehl: If we no longer want to use oil or gas in the future, hydrogen could be an attractive alternative. A lot of research is being carried out in this area, especially in the field of mobility. Specifically, this involves fuel cells. As iinovis, we have designed several fuel cell systems for customers in our recent company history, more specifically the stacks and humidifiers. Why? Because we have always been good at simulation, design and the choice of materials. And importantly, you have to have an idea of what performance the thing needs to deliver in the end. Put simply, a fuel cell converts gases into electricity. We need it for everything. Light, heating, but also increasingly for e-mobility. In order for this chemical process to take place cleanly and with an efficient yield, the fuel cell needs very specific conditions. We have developed a new system that can flexibly simulate these conditions.

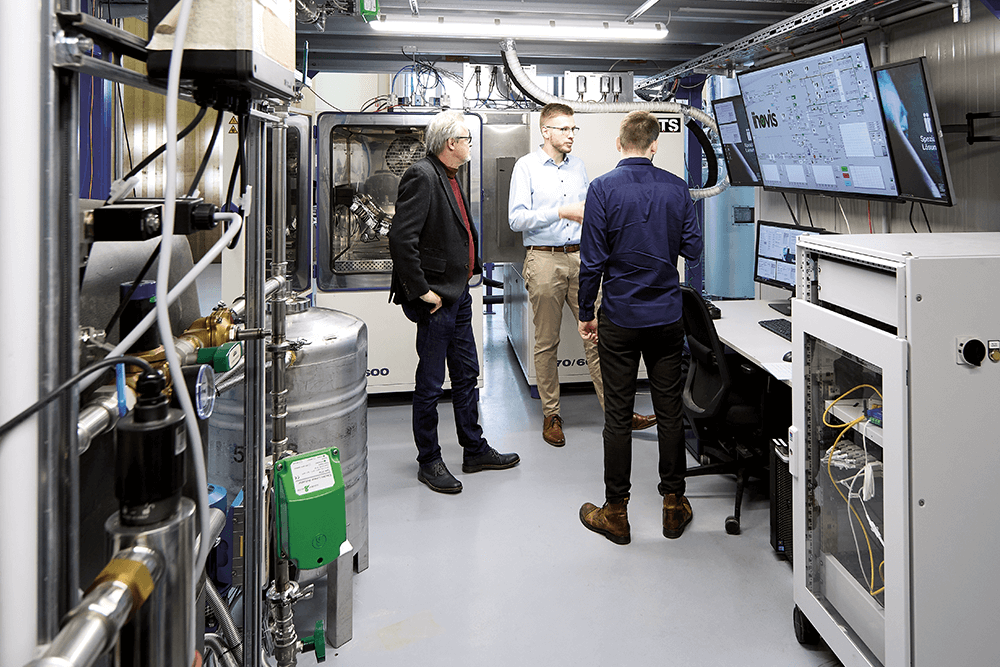

The measured values at a glance: Philipp Knothe (centre), development engineer at iinovis, shows the dataTec SPEKTRUM team the heart of the system. dataTec Business Development Manager Dirk Bubley (left) is pleased to see the NI LabVIEW software distributed by dataTec in use.

Peter Diehl: It's mainly about boundary conditions: What happens to a car if the fuel cell system draws in air with a very high or very low level of humidity? A car manufacturer must be able to be sure that the end customer's car will not break down. We give our customers security with the test system.

Andreas Groß: Sometimes people ask companies like us where we think the journey is going. Will we all be driving electrically in 20 years' time? I'm glad that we don't feel compelled to draw up such a roadmap. But the road there is incredibly exciting. I love sceptics and see them as a challenge. We at iinovis see ourselves as drivers. In the end, however, it is others who make the big decisions.

Peter Diehl: Measurement technology helps us to make our testing more accurate, more measurable and the results more reproducible. We have systems that allow you to simulate two decades of solar radiation. We also specialise in "airbag shooting". Does it deploy correctly? Does the driver only get it in the face in the end? Does the technology work under all temperature conditions? You can only guarantee all of this if you have the right measurement technology for testing. Automation also plays a role. This is where companies like dataTec help us with their comprehensive application expertise and suitable software.

The joint discussion with CEO Andreas Groß and Vice President Innovation Peter Diehl clearly shows that iinovis is breaking new ground with its fuel cell humidifier testing system to support customers with their challenges.

Would you like to find out more about the technology and how the system works? Then read on and discover the future of testing!

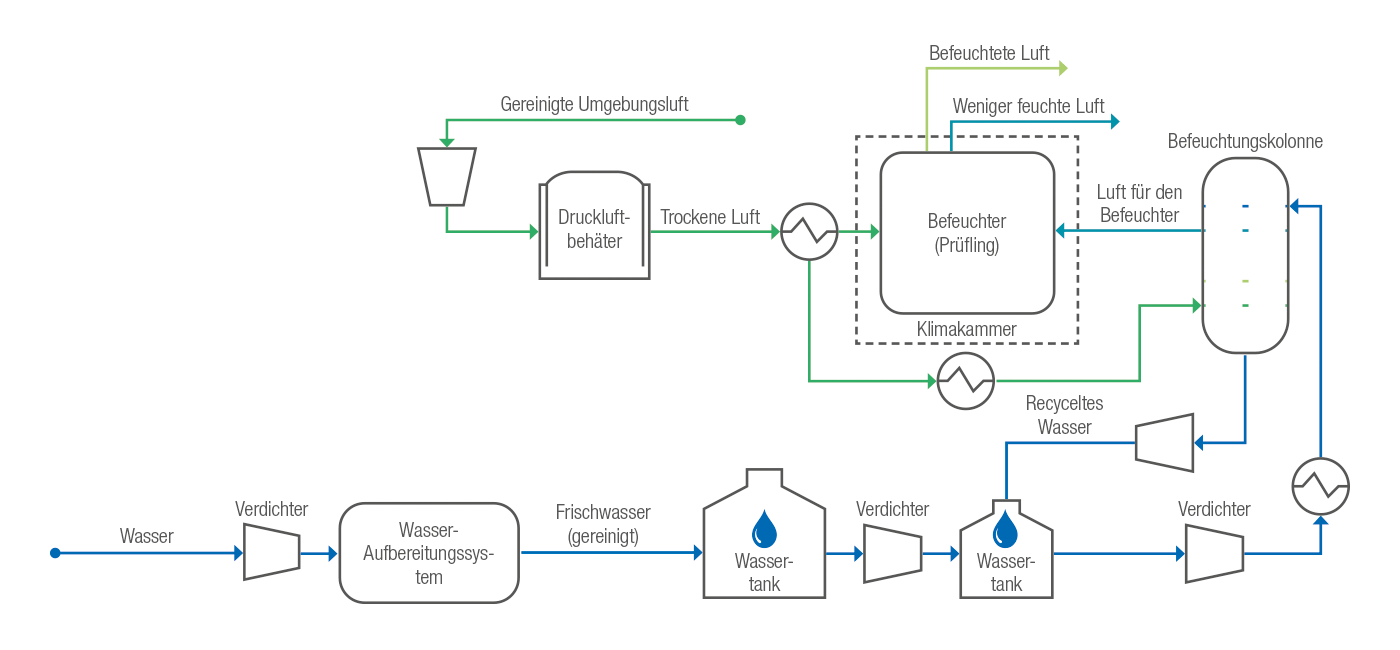

Fuel cells are proving to be a sustainable drive concept for climate-friendly vehicle applications. In order for a PEM fuel cell (PEMFC, polymer electrolyte membrane fuel cell) to function optimally and with ageing stability, membrane air humidifiers are used to ensure a balanced oxygen and water balance within the system. Here, some of the water present in the humid exhaust air from the fuel cell stack is released into the filtered, dry intake air via a semi-permeable membrane.

The iinovis GmbH humidifier test bench can be used to test the operating behaviour of different humidifier concepts under various operating conditions. The test stand supports the further development of prototypes and is also used for quality and functional testing of series products.

Testing a humidifier unit.

Humid air is produced under controlled conditions and fed to the humidifier (test specimen) in a climate chamber. By injecting fine water droplets, the test bench can simulate the supersaturated exhaust air of a fuel cell. The setting and measurement parameters include the pressure and mass flow, temperature and droplet size. This means that all temperature and power ranges of different fuel cells can be simulated.

Function of the membrane humidifier.

The humidifier defines the humid fresh air that is supplied to the fuel cell stack. This prevents the cathode of the membrane electrode assembly (MEA) from drying out. A balanced moisture content prevents premature ageing of the fuel cell membrane and ensures the specified system performance.

Measurement technology used.

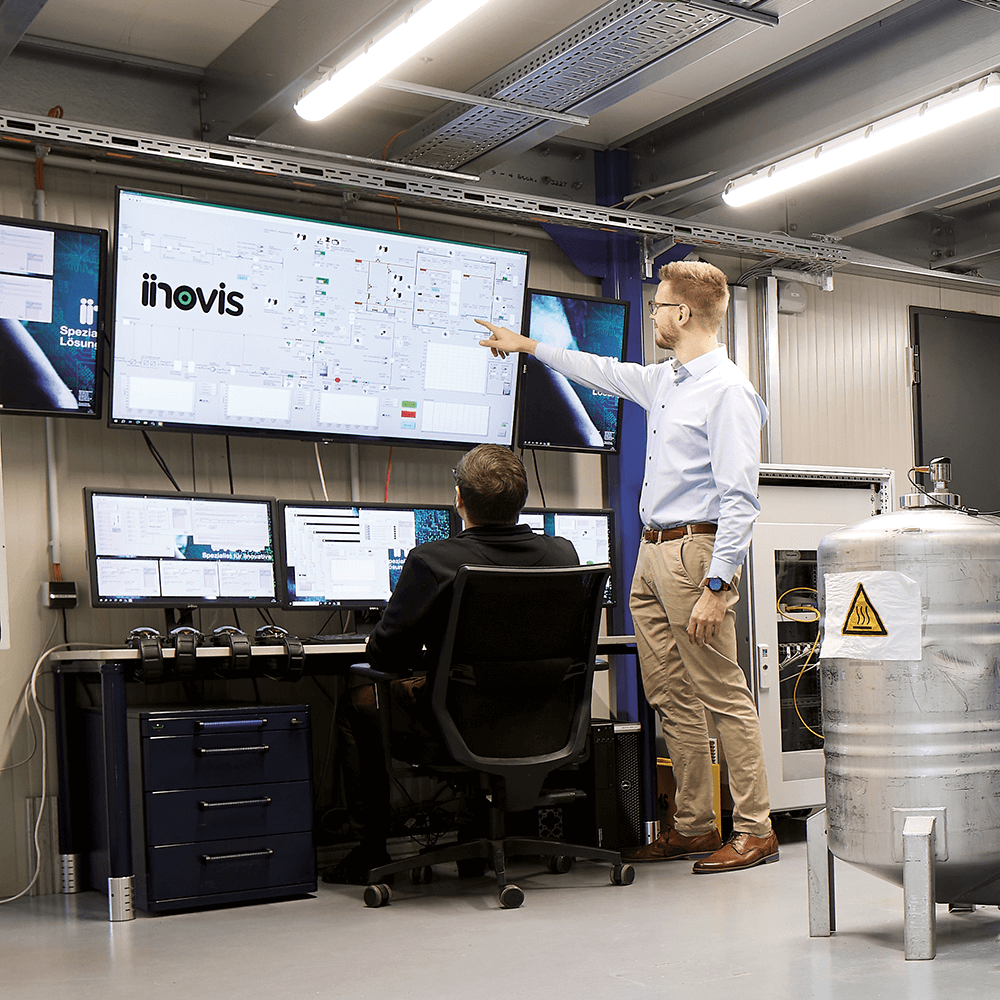

The information from the test environment is digitised via sensors and passed on to measuring devices, e.g. a data logger. The measurement sequences are automated by the higher-level NI LabVIEW software. This allows them to be quickly set, adapted or even restarted.

Data evaluation.

The measurement data is processed and analysed on a customer-specific basis and summarised in result reports. The operating characteristics of the humidifier can be evaluated directly on the basis of the visualisation. The knowledge gained can then be used for further development.

Hardware

NI's electronic measurement and test technology offers high-quality modular measurement devices and I/O components for building customised, automated test systems. The products include application-specific modules and FPGA-capable hardware for industrial development and production. External hardware components can be controlled and monitored with special data acquisition and control products designed for specific sensors. Components from the CompactDAQ, CompactRIO and PXI platforms are used.

Software

The LabVIEW graphical programming environment supports the development of automated test systems and enables quick access to the hardware. The NI software DIAdem is available for future extensions and as a supplement to LabVIEW. With DIAdem, even larger amounts of data can be managed and analysed. This means that the current system is already future-proof.

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.