#statusMessage#

Do you want to start the comparison now?

#statusMessage#

Do you want to start the comparison now?

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Disturbances in the power grid often go unnoticed until systems shut down or equipment fails. Regular power quality asse...

In this practical checklist you will learn how to calibrate your measuring and test instruments effectively – simply, ef...

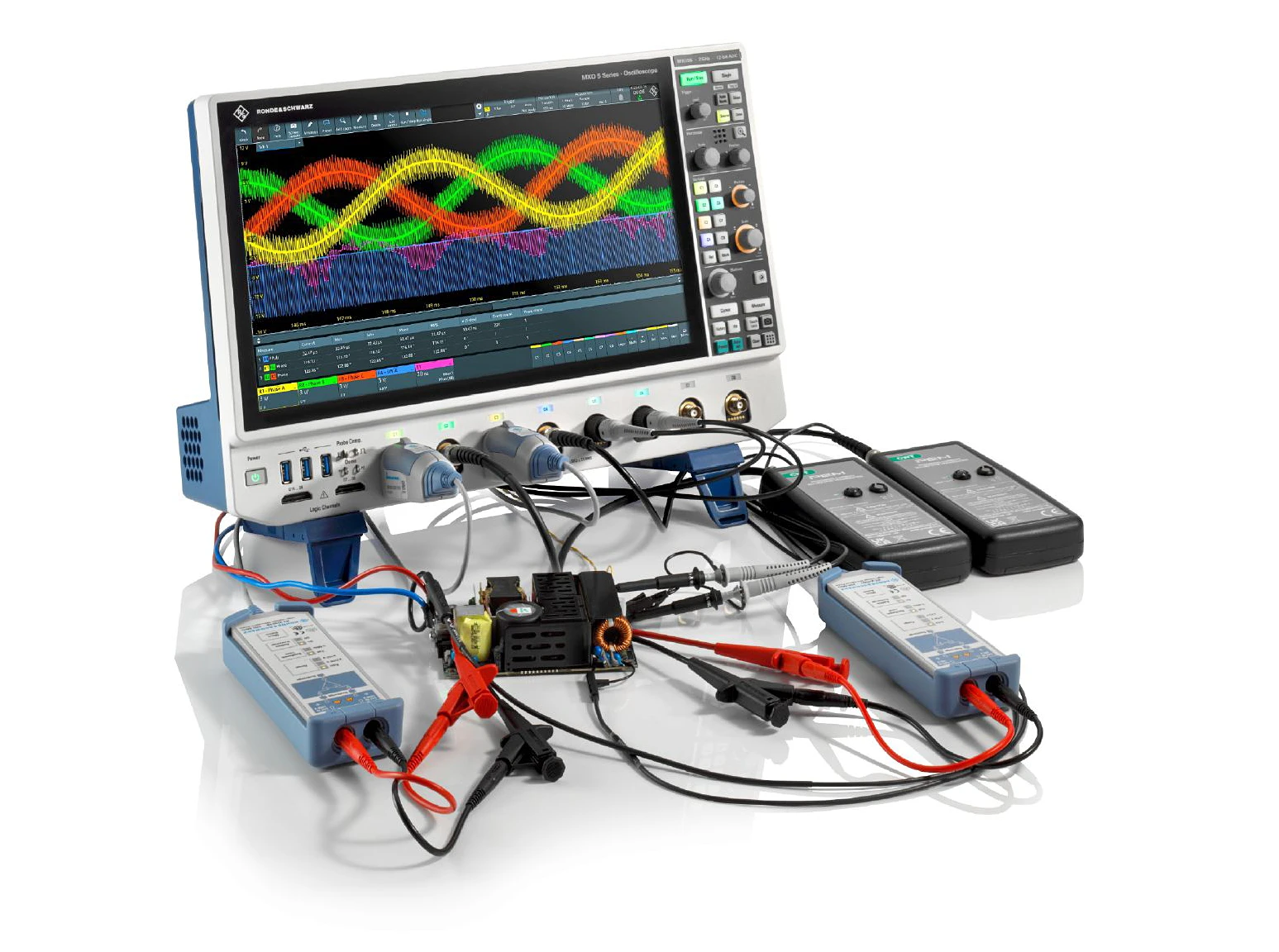

Modern oscilloscopes of the MXO Series from Rohde & Schwarz enable precise analysis and optimization of electric drivetr...

Embedded systems applications are growing rapidly in the automotive industry. Many vehicle designs use CAN, LIN or FlexRay to communicate among electronic control units (ECUs), and between ECUs and sensors, actuators and displays. These buses are critical in providing real-time communications in and among important subsystems from braking systems to infotainment systems. CAN, LIN, and FlexRay are relatively mature bus protocols and are designed to be robust and easy to integrate. Even so, communications can be impacted by noise, board layout, and power-up/down timing. Problems can include excessive bus errors and lock-ups.

Unlike basic protocol analyzers, oscilloscopes equipped with protocol decoding, an be used to see both the decoded bus traffic, as well as signal quality. Perhaps more importantly, oscilloscopes can be used to troubleshoot problems at the system level. Automobiles rely on extensive networks of sensors, actuators and displays, and many problems involve bus timing relative to I/O events or values. Oscilloscopes are well-suited for looking at I/O signals and bus transactions at the same instant. This ability to see bus signals and decoded traffic at the electrical level and systems level make oscilloscopes the best choice for troubleshooting.

Learn why oscilloscopes are the best choice for troubleshooting in this application note from Tektronix.