#statusMessage#

Do you want to start the compare now?

#statusMessage#

Do you want to start the compare now?

Our electromagnetic environment is heavily burdened due to the multitude of transmitters and sources of interference pre...

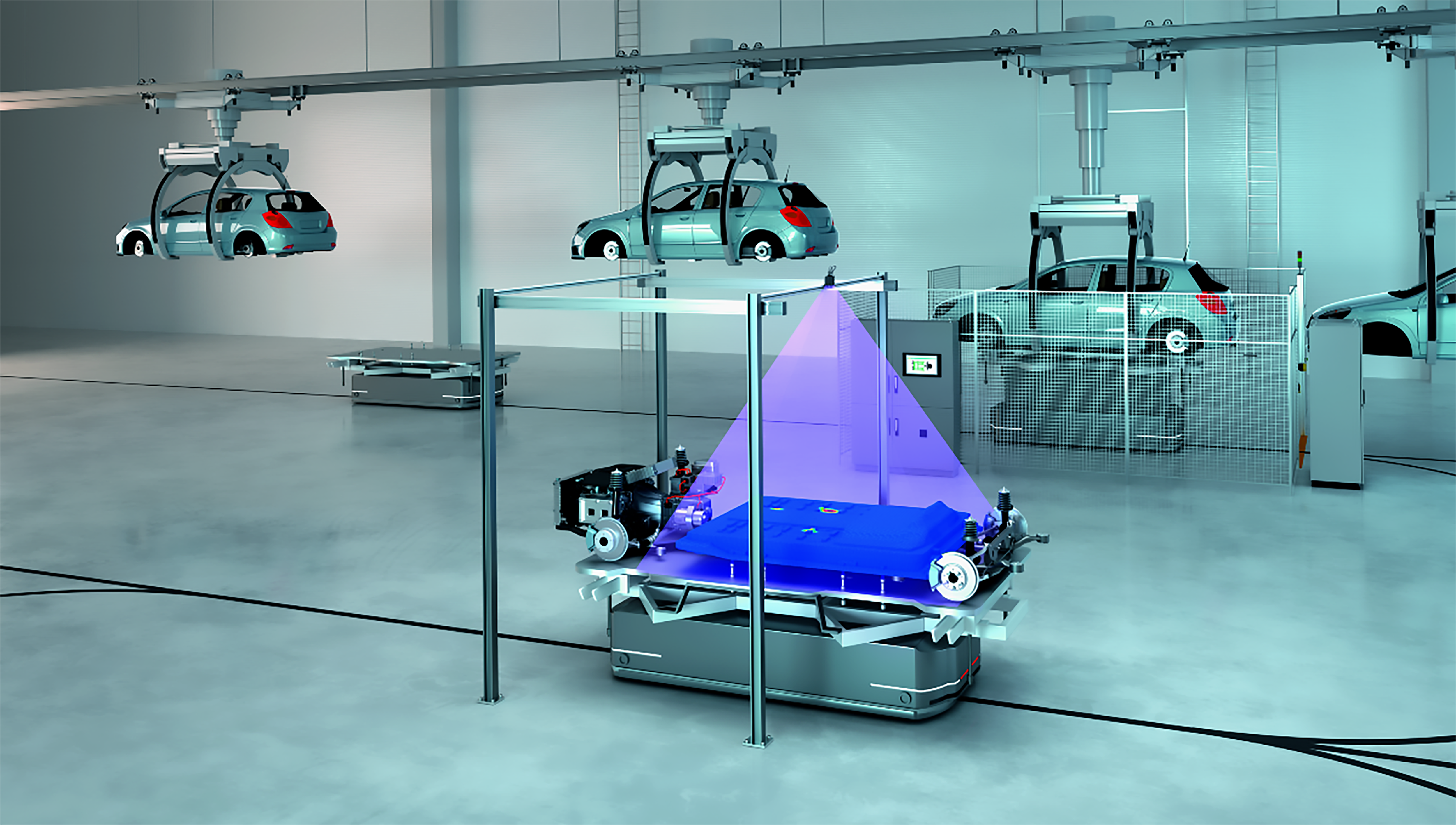

Automated test and measurement systems that are fully connected with instrumentation and test data can significantly inc...

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

Electric vehicles are the future - but what happens to the batteries when they can no longer be used in cars? Efficient ...

Immerse yourself in the world of process engineering and deepen your knowledge. Our experts are ready to shed light on all facets of measurement technology in process engineering with you.

In simple terms, process engineering covers all industrial processes in which raw materials such as gases, liquids or solids are converted into a finished product or intermediate product for further processing. Process engineering encompasses the planning, design, control, monitoring, and optimisation of production processes.

A production process involves many steps - starting with the choice of the raw materials through the various processing stages through to the finishing of the final product. A simple example of process engineering is the production of bread. The process starts with the choice of the ingredients such as flour, water, yeast, and salt. These are then mixed, kneaded, shaped, and baked in defined quantities to produce the finished bread.

Particularly in more complex industrial applications in fields such as chemicals, pharmaceuticals, food production, automotive manufacturing and many others, process engineering is used to create efficient production processes and ensure that product quality meets the desired standards.

Measurement technology plays a decisive role in process engineering. It is used to collect and monitor relevant parameters of materials, products, or process equipment. The various aspects of measurement technology ensure that production is carried out efficiently and with optimum quality:

Measurement technology supports the continuous improvement of industrial processes by providing the necessary data and information that contributes to decision-making. This enables companies to increase the efficiency and quality of their production and ensure their competitiveness. Measurement technology fulfils various tasks here:

Challenge us and send your own question to

frag‑uns[at]datatec.eu

We look forward to hearing from you!

Many special sensors are used in process engineering. The choice of sensor depends on the type of process, the parameters to be measured and the ambient conditions. These are the most common sensors:

Calibration is essential in the field of process engineering, as only calibrated measuring instruments and sensors provide reliable measurement data. Through regular calibration, companies can strengthen confidence in their measuring instruments and ensure that the measured values are consistent and reliable.

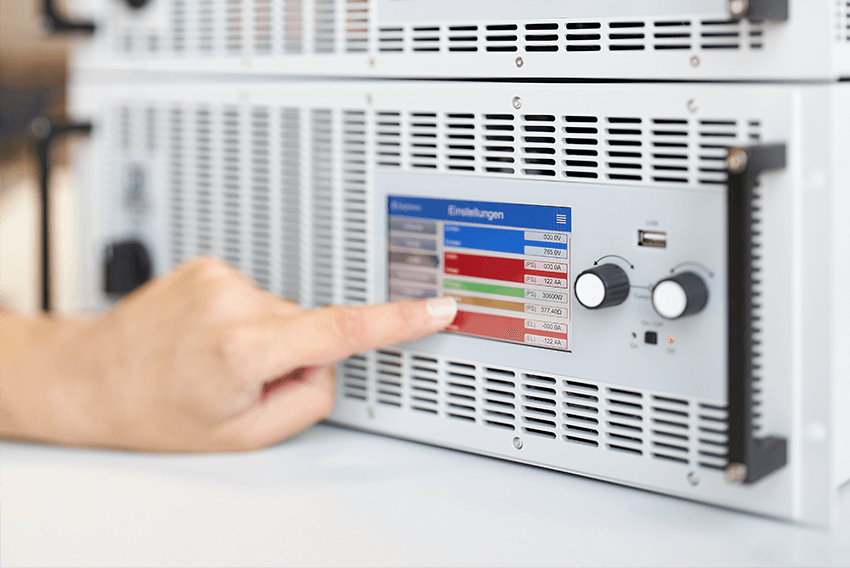

Calibration devices for process engineering should always provide reliable measurement results and fulfil the legal requirements with regard to measurement functions, limit values, documentation obligations, etc. The following quality criteria are relevant when selecting the right calibration device:

Some questions can be answered easily and directly on the phone. Just call us. Our experts will be happy to assist you.