#statusMessage#

Do you want to start the comparison now?

As electronic components become increasingly complex and time-to-market pressures continue to grow, operating costs for automated test systems remain a constant focus. Intelligent investment decisions in the development, deployment, operation, and maintenance of a customized automated test system can enhance overall profitability.

This applies equally to changing test requirements and future system modifications—for example, in the case of portfolio adjustments. Variable test functions for different electronic components, flexible connectivity options for the device under test (DUT), and scalable hardware and software ensure that throughput requirements can be met.

A PXI system is an optimal, cost-efficient solution characterized by scalability and precision. Its high channel count meets even demanding throughput requirements. The modular design allows multiple instruments to be consolidated, saving both space and weight. Throughput and weight advantages can reduce deployment costs compared to conventional test systems—for example, by lowering capital expenditures through fewer required test systems, minimizing integration effort, or reducing shipping and logistics costs.

As the developer of the PXI platform and the graphical development environment LabVIEW, NI has supported companies for over 40 years in developing highly efficient automated test systems. NI’s industry-leading PXI systems comprise high-performance, modular measurement instruments and I/O modules featuring advanced software and synchronization functions. They are particularly well suited for high-channel-count test applications, automated production testing, and device validation.

NI is a founding and leading member of the PXI Systems Alliance (PXISA), which defines and governs the open PXI industry standard. NI systems can be combined with PXI products from more than 70 vendors.

NI PXI hardware leverages state-of-the-art technologies, integrating high-performance multicore processors and FPGAs to optimize measurement range and overall system performance.

The PXI industry standard defines exceptionally strict specifications for frequency stability and accuracy. Users can rely on their test systems to deliver the required production test results consistently.

The PXI architecture enables synchronized measurements across multiple modules and chassis, allowing system expansion to accommodate evolving hardware and software requirements.

PXI (PCI eXtensions for Instrumentation) is a software-defined platform for measurement and automation systems. It combines high performance with cost-efficient channel density—ideal for test applications in manufacturing, aerospace, machine monitoring, and automotive environments. PXI systems have been available since 1998 and have evolved into an open industry standard that ensures interoperability and compliance with the stringent mechanical, electrical, and software requirements defined by the PXI architecture.

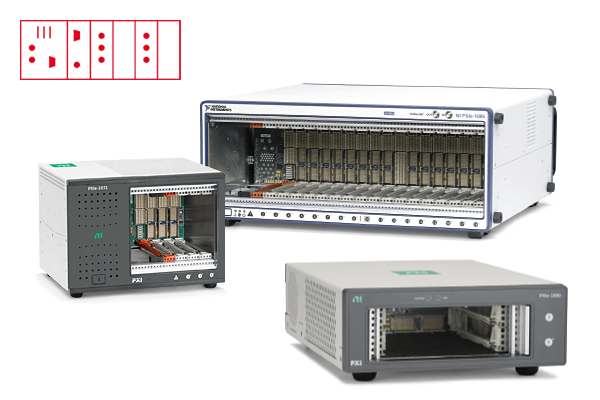

A PXI system consists of three hardware components: chassis, controller, and peripheral modules. PXI chassis are based on standard PC-based PCI and PCI Express bus technology, combining a rugged mechanical enclosure with essential timing and synchronization features.

The rugged enclosure forms the backbone of a PXI system. It provides power, cooling, and the communication bus. Depending on the model, two to eighteen module slots are available, allowing configuration of the measurement system as a portable, benchtop, rack-mount, or embedded solution.

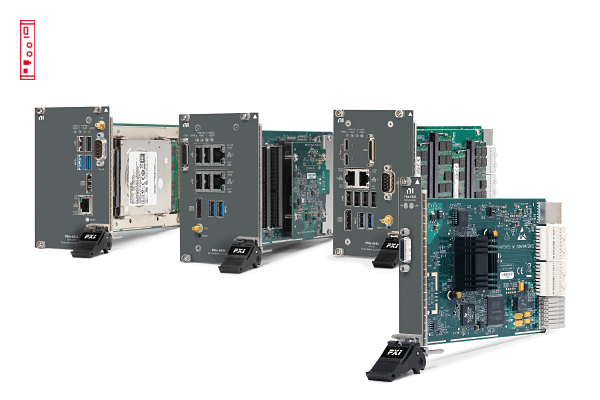

PXI controllers can be either embedded or remote. An embedded controller allows operation of the PXI system without an external PC. Remote controllers enable control via a laptop or host computer.

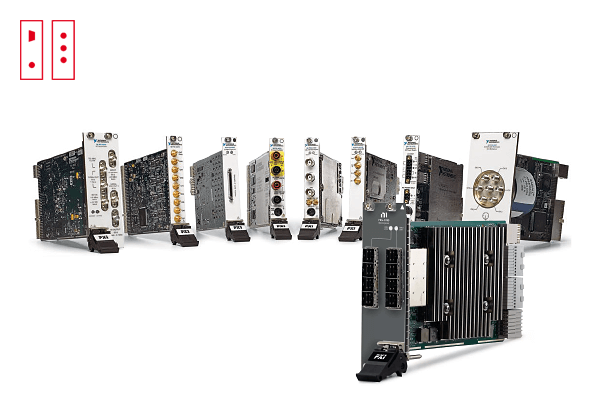

PXI modules provide measurement and I/O functionality that can be integrated into the system architecture. They offer the modular flexibility required to build scalable, application-specific test systems.

NI software optimizes data acquisition and test efficiency. The portfolio covers the full range from interactive exploration and test development to system and data management, enabling actionable insights at scale. NI software represents a leading standard in measurement technology. Special licenses for research and education make these benefits accessible even for limited budgets.

PXI systems are software-defined. The software enables easy adaptation and reconfiguration of systems to meet evolving test requirements. Using PXI together with software such as LabVIEW and TestStand allows efficient implementation of validation, production, and application tests—for example, end-of-line (EOL) testing of IoT devices.

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.